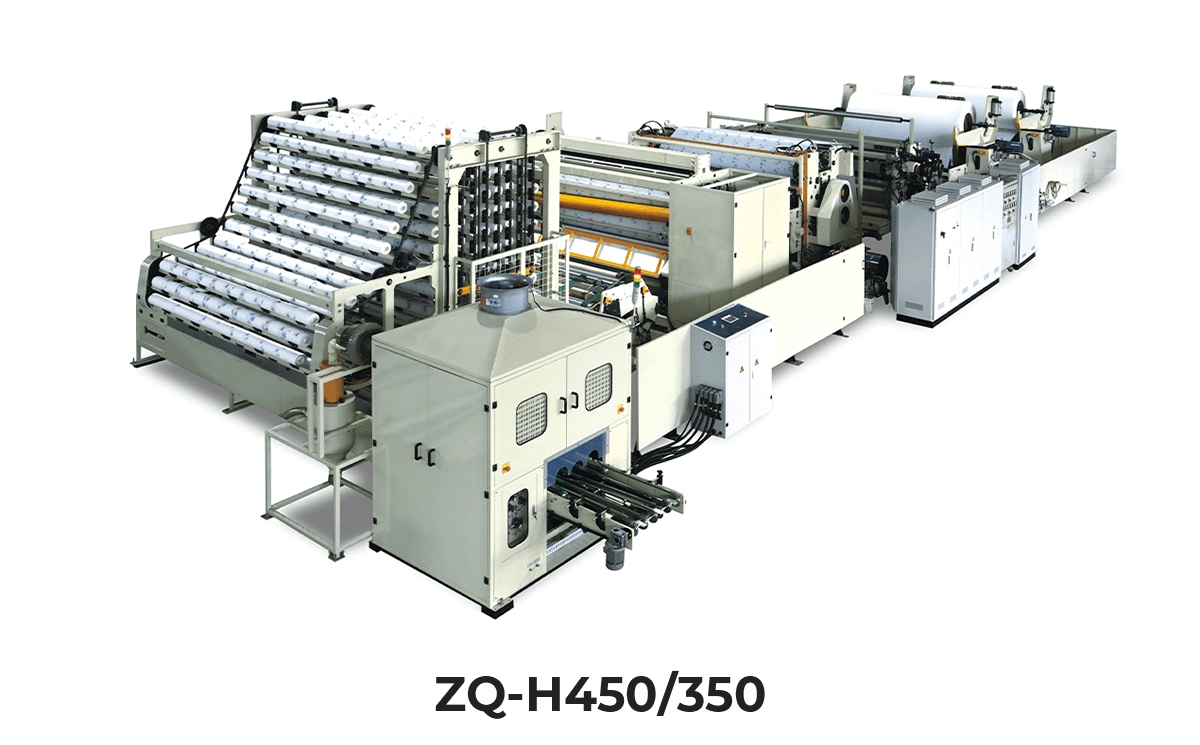

1.Non-stop type machine continuously rewind.

2.Each unit is driven by independent motor(servo motor); Simple structure decreases failure rate.

3.Servo motor controls machine hand and break the web at perforation line steadily and precisely.

4.Adopt high-precision NC machined large diameter blade shaft, and Siemens SIMOTION system, and automatic blades axial slid function, guarantee perforation is precise and clear, and the rolls have finest tightness and diameter.

5.Use constant-vacuum system to start rewinding coreless roll, faster and less wrinkles.

6.Multipurpose production line: it could also produce JRT products.

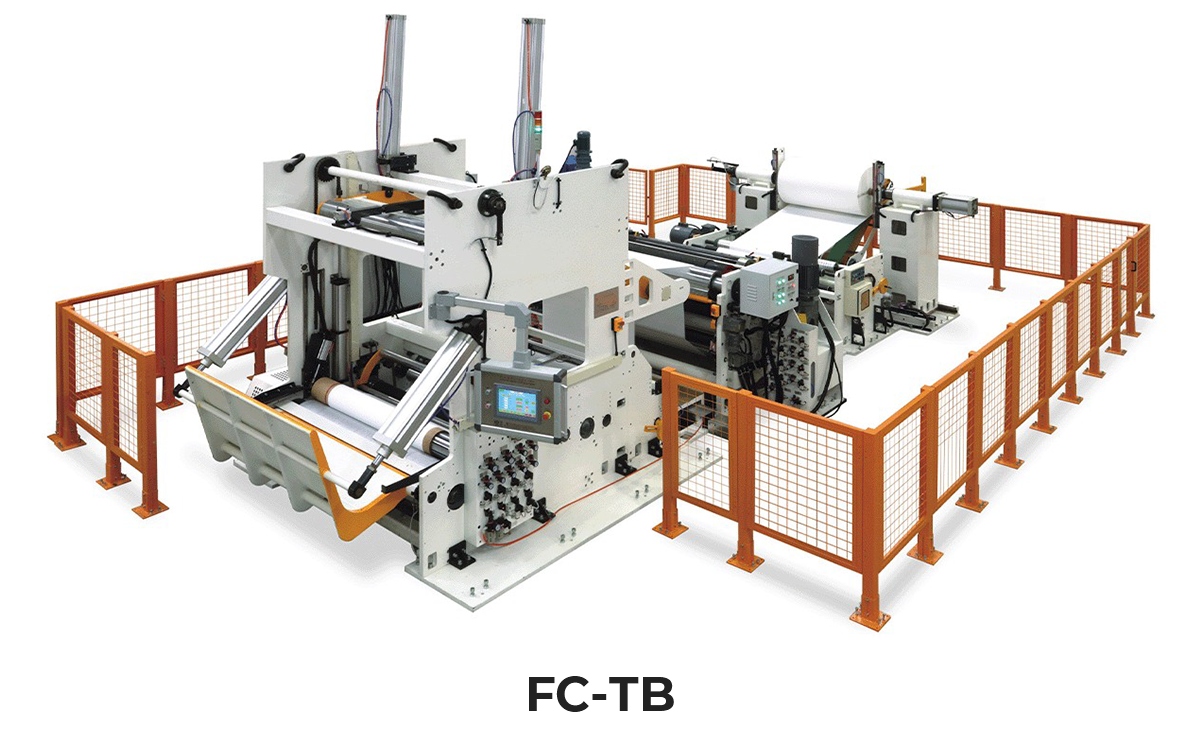

Our toilet paper slitting machines are designed for precision and speed. They effectively cut large tissue jumbo rolls into smaller, consumer-sized toilet rolls, ensuring clean edges and consistent sizes. These toilet roll cutting machines are ideal for high-volume production lines and can be customised based on roll dimensions, cutting patterns, and output capacity.

Advantages:

- High-speed slitting and cutting

- Adjustable blade spacing

- User-friendly interface for efficient operation

- Compatible with various paper grades

Enhance the texture and visual appeal of your toilet paper with our toilet paper embossing machines. These machines are designed to imprint custom patterns and textures onto tissue rolls, improving softness, absorbency, and brand identity. Whether you're using point-to-point or steel-to-paper embossing, we offer options that integrate seamlessly with your production line.

Benefits:

Custom embossing patterns

Improved tissue softness and appearance

Consistent embossing pressure

Our toilet paper rewinding machines are essential for converting jumbo tissue rolls into consumer-ready toilet rolls. The rewinding system ensures tight, uniform rolls and allows for core or coreless production, depending on your requirements. Ideal for integration with slitting and embossing systems, these machines help automate and streamline your production process.

Highlights:

Fully automatic and semi-automatic models available

Core and coreless rewinding

Adjustable speed control

High output with minimal paper waste