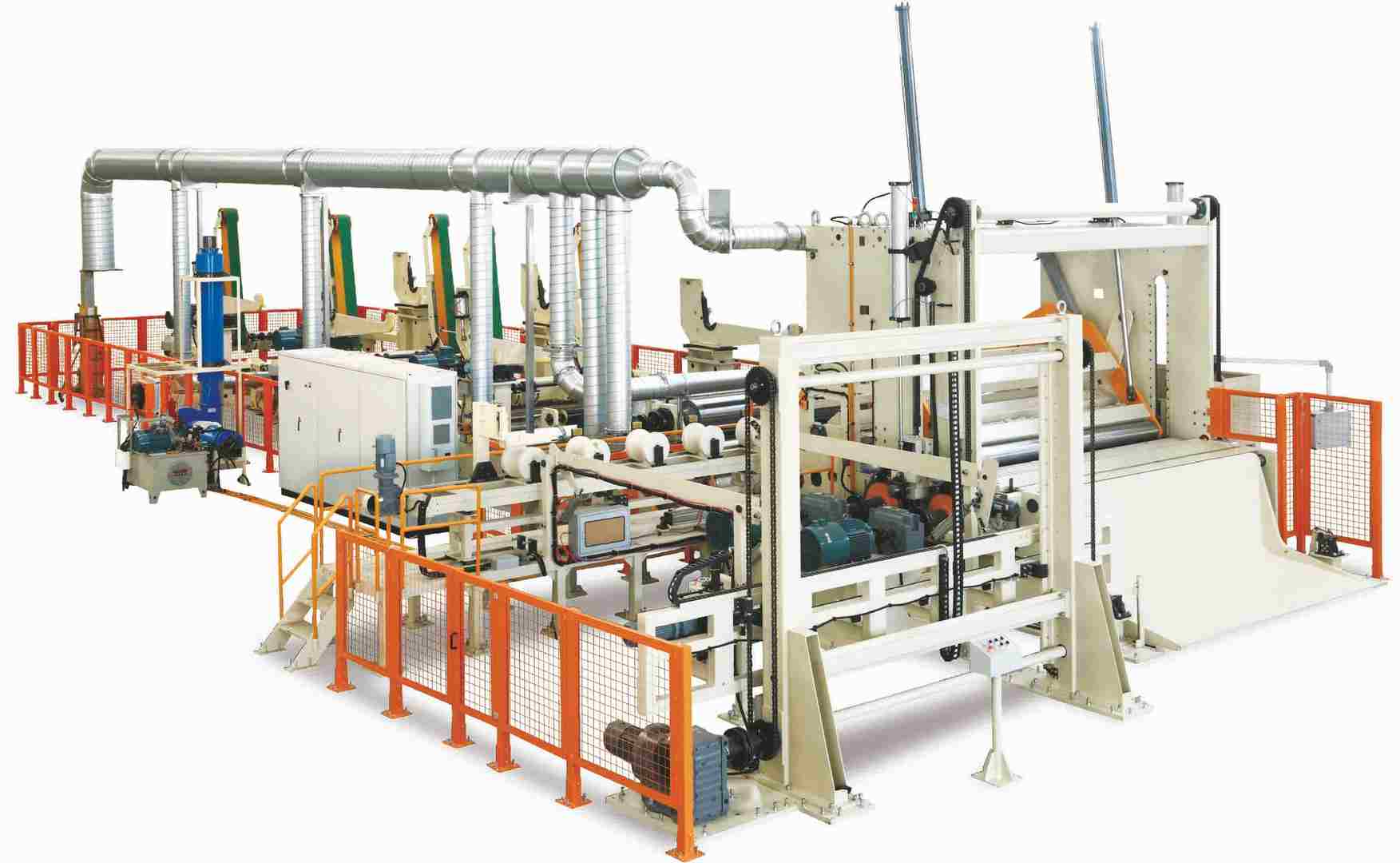

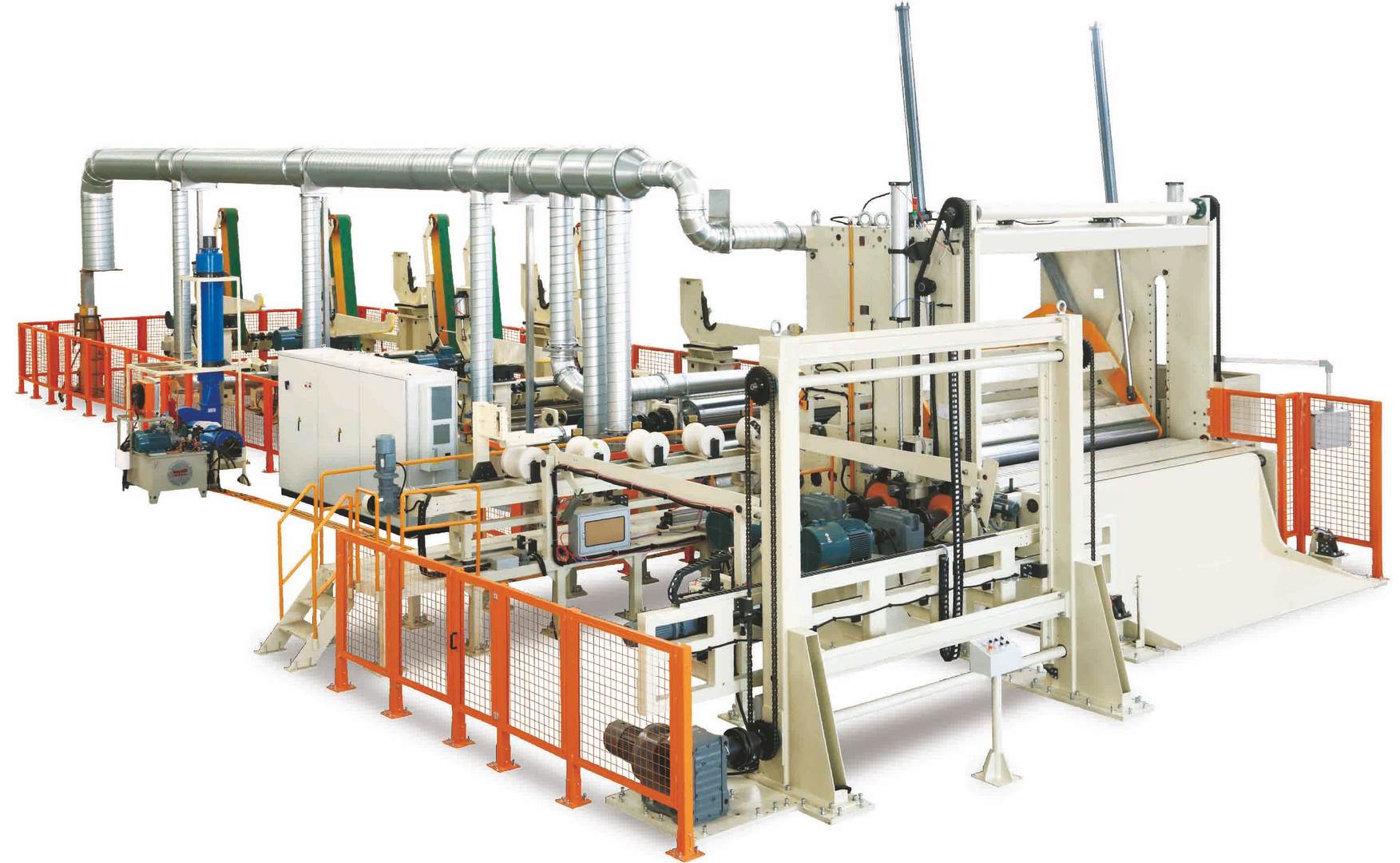

1.Easy operation, labor-saving: The entire production process, from raw materials to packaging, is fully automated, reducing manual intervention. The user-friendly fully automatic folding production line allows one person to operate multiple machines, saving 75% of labor costs.

2.Stable operation, increased capacity: Compared to a semi-automatic folding production line, the fully automatic system is not limited by operator efficiency, resulting in improved production efficiency and increased capacity.

3.Improved product hygiene: Full automation reduces potential contamination and hygiene risks associated with manual operations, ensuring higher product hygiene standards.

4.Accurate stacking and folding: The precise stacking and counting system improves the product's pass rate.

5.User-friendly automated roller maintenance system.

6.Optional first-pull half-fold function: Designed for convenient access to tissues after opening the packaging.