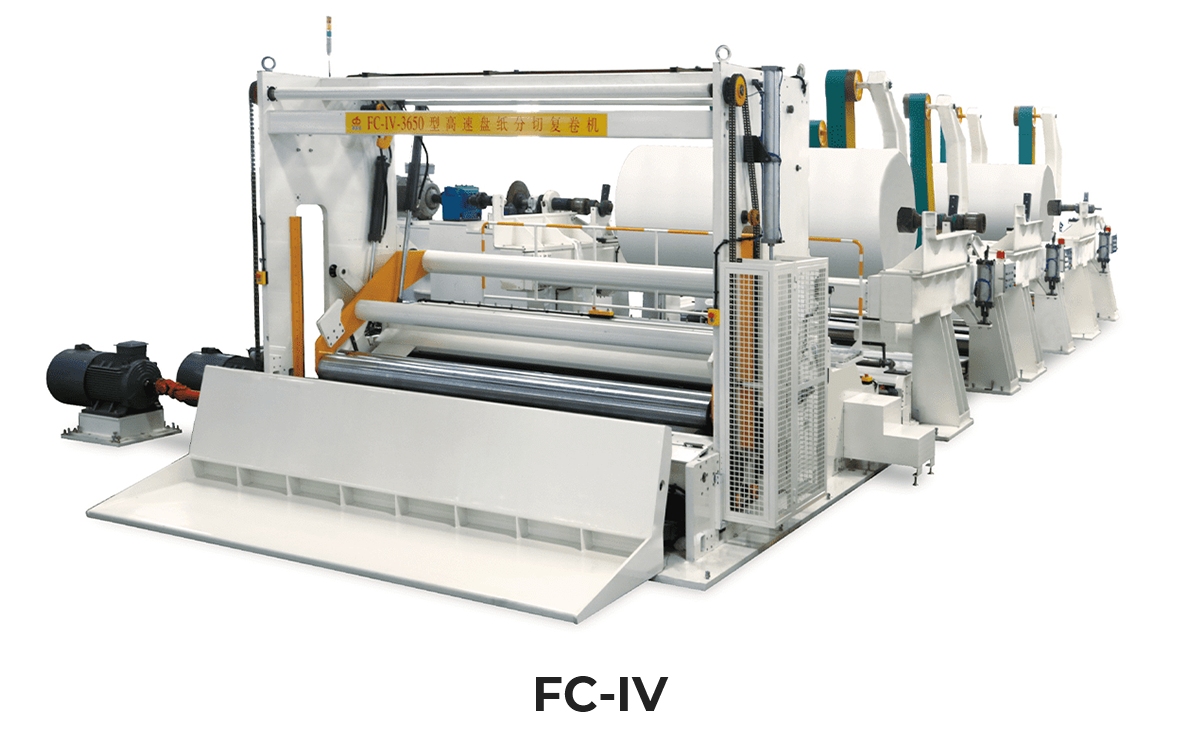

1.Adopt PLC&HMI, easy to operate the machine.

2.Each part is driven by independent variable frequency motor and synchronous belt,which guarantee the perforation and total length accuracy.

3.Electric & pneumatic controlled brake is much more steady and faster.

4.Automatic tail trimming gluing sealing.

5.Multipurpose production line:it could also process JRT products.

Our Tissue Roll Rewinder Machines are engineered to unwind jumbo parent rolls and rewind them into compact, evenly wound tissue logs ready for cutting and packaging. Designed for both speed and stability, these machines support continuous production while ensuring consistent tension and roll alignment.

Ideal for converting toilet tissue, kitchen towel, or facial tissue, this equipment can be customised to suit various paper grades, roll sizes, and core types. Whether for high-volume manufacturing or private label production, our rewinder machines provide reliable, efficient performance.

Benefits:

Smooth and stable rewinding process

Adjustable tension and roll dimensions

Suitable for various paper types and core sizes

High-speed output with consistent log formation

Easily integrates into full tissue converting lines

Our Tissue Roll Cutting Machines are designed for accurate and efficient conversion of tissue logs into finished, consumer-sized rolls. Working seamlessly after the rewinding process, these machines use high-speed rotary blades to deliver smooth, consistent cuts with minimal dust and waste.

Ideal for toilet paper, kitchen towel, and other tissue roll types, the machine ensures uniform length and clean edges—essential for high-quality packaging and presentation. Customisation options are available to match your roll sizes, blade settings, and production needs.

Advantages:

High-speed and precise log cutting

Clean, dust-free edges

Consistent roll length and diameter

Compatible with rewinding and packaging lines

Customisable for different tissue roll specifications

Our Toilet Tissue Paper Wrapping Machines are built for efficient and consistent packaging of consumer-sized toilet rolls. Designed to streamline the final stage of your tissue production line, these machines can wrap single rolls or multi-roll packs in plastic film or paper material, ensuring neat appearance and protection during storage and transport.

With adjustable settings, fast changeovers, and smooth automation, this equipment is ideal for high-volume manufacturers aiming to improve packaging speed and reduce labour costs. The system can be customised based on wrapping material, roll count per pack, and pack size requirements.

Highlights:

High-speed automatic wrapping

Compatible with various pack formats

Neat sealing and stable performance

Adjustable for different roll sizes and materials

Supports plastic film or paper-based packaging