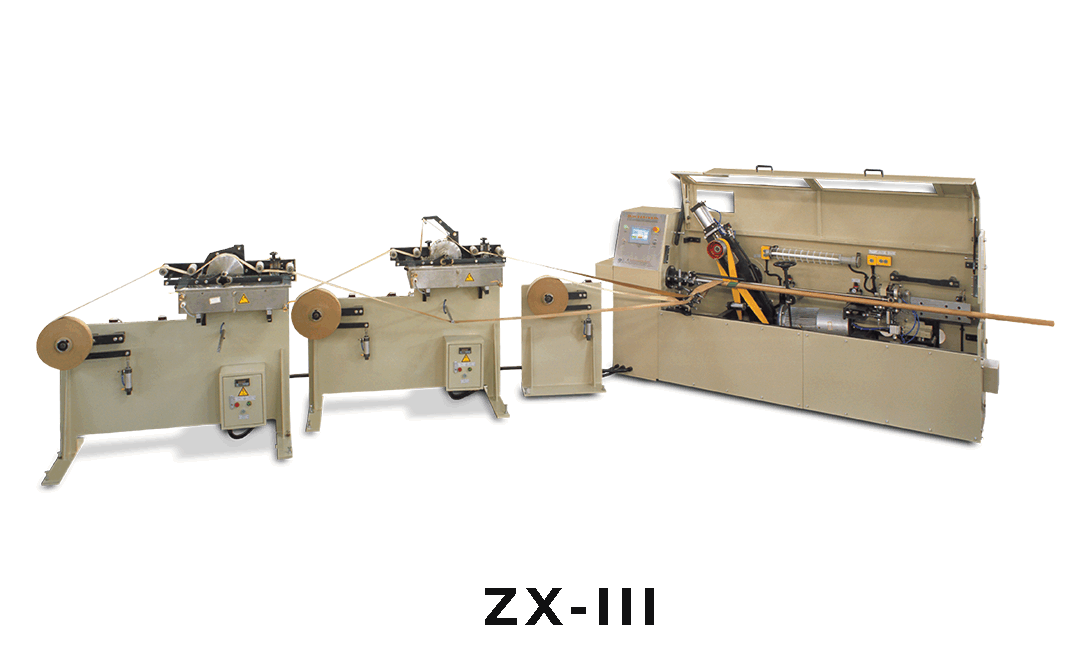

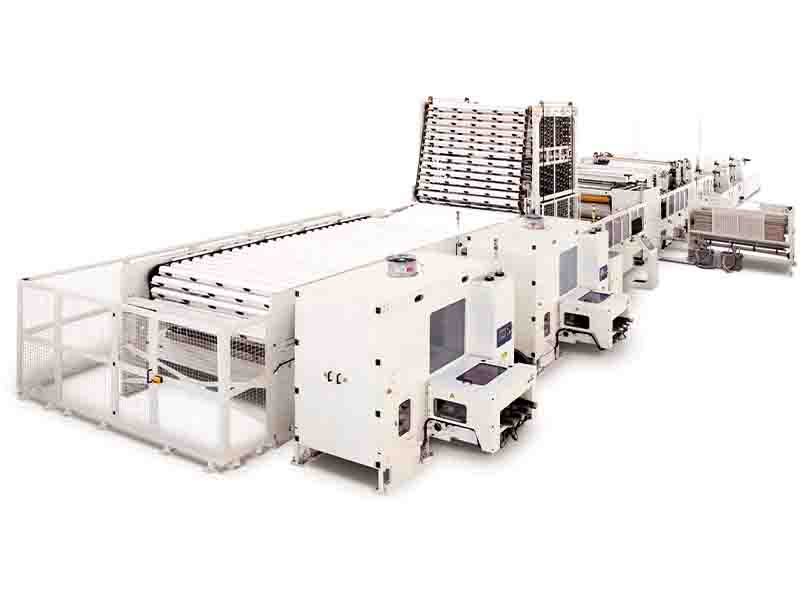

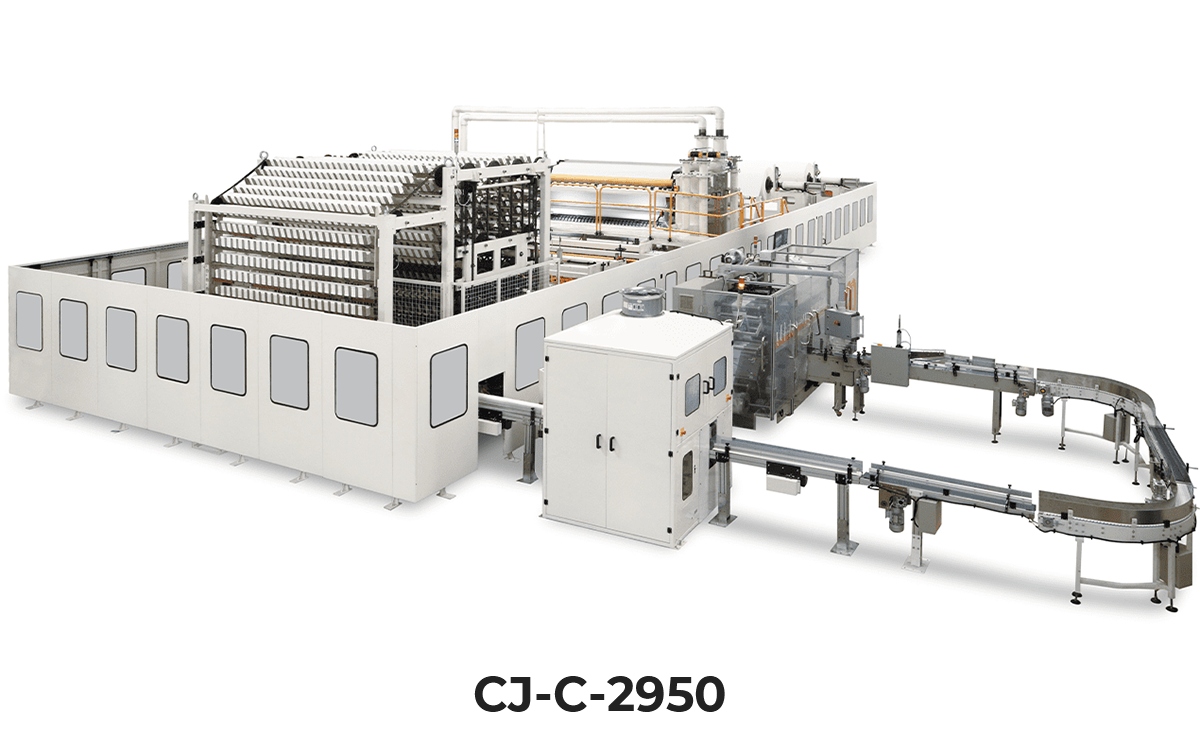

1.Precision and Customization: Paper core machines create accurately sized cardboard cores tailored to specific tissue products.

2.High Production Efficiency: Paper core machines operate at high speeds, producing a large number of cores quickly.

3.User-friendly and Low Maintenance: Paper core machines are easy to operate, require minimal training, and have simple maintenance procedures.

4.Durability and Reliability: Paper core machines are built to last, ensuring consistent performance and reducing the risk of breakdowns.

5.Safety Features: Paper core machines prioritize operator safety with built-in safety measures.

6.Integrated Workflow: Paper core machines seamlessly integrate into the tissue production line, streamlining the production process.