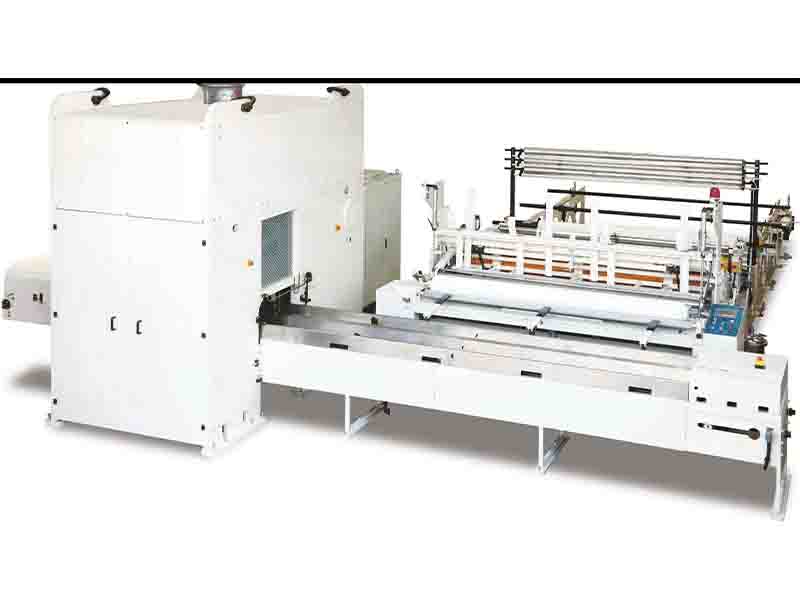

High-Speed, Automated Rewinding

The Automatic Tissue Rewinder allows rapid conversion from jumbo to retail-sized rolls, achieving speeds ranging from mid- to high-speed —driving daily output and reducing bottlenecks .

Versatile Substrate Management

Tailored to accommodate single-ply and multi-ply formats, with flexible configurations for varying core diameters. Models include fully automatic feed, auto core-changing, edge trimming, glue spraying, and sealing functions.

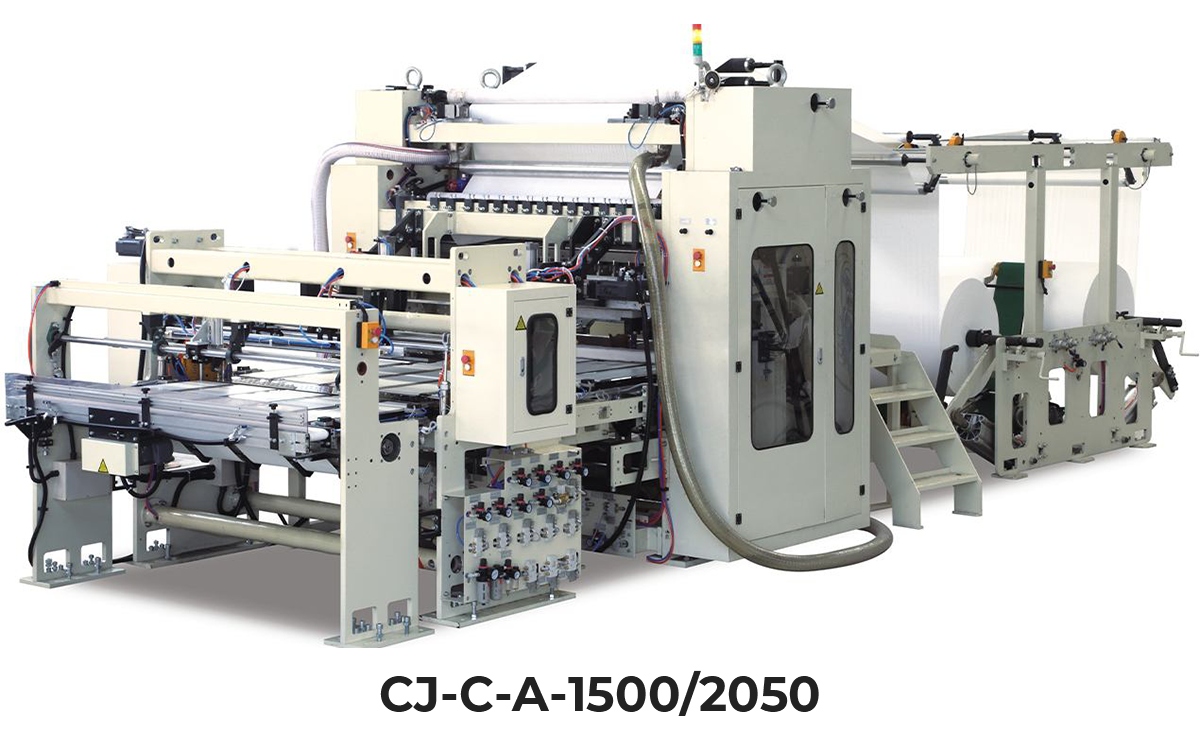

Enhanced Process Reliability & Automation

Equipped with advanced PLC-based control systems, touch-screen interfaces, and servo-driven functions, the machine supports automatic tail-trimming, seamless core loading, and synchronized slitting—ensuring precision and minimal downtime .

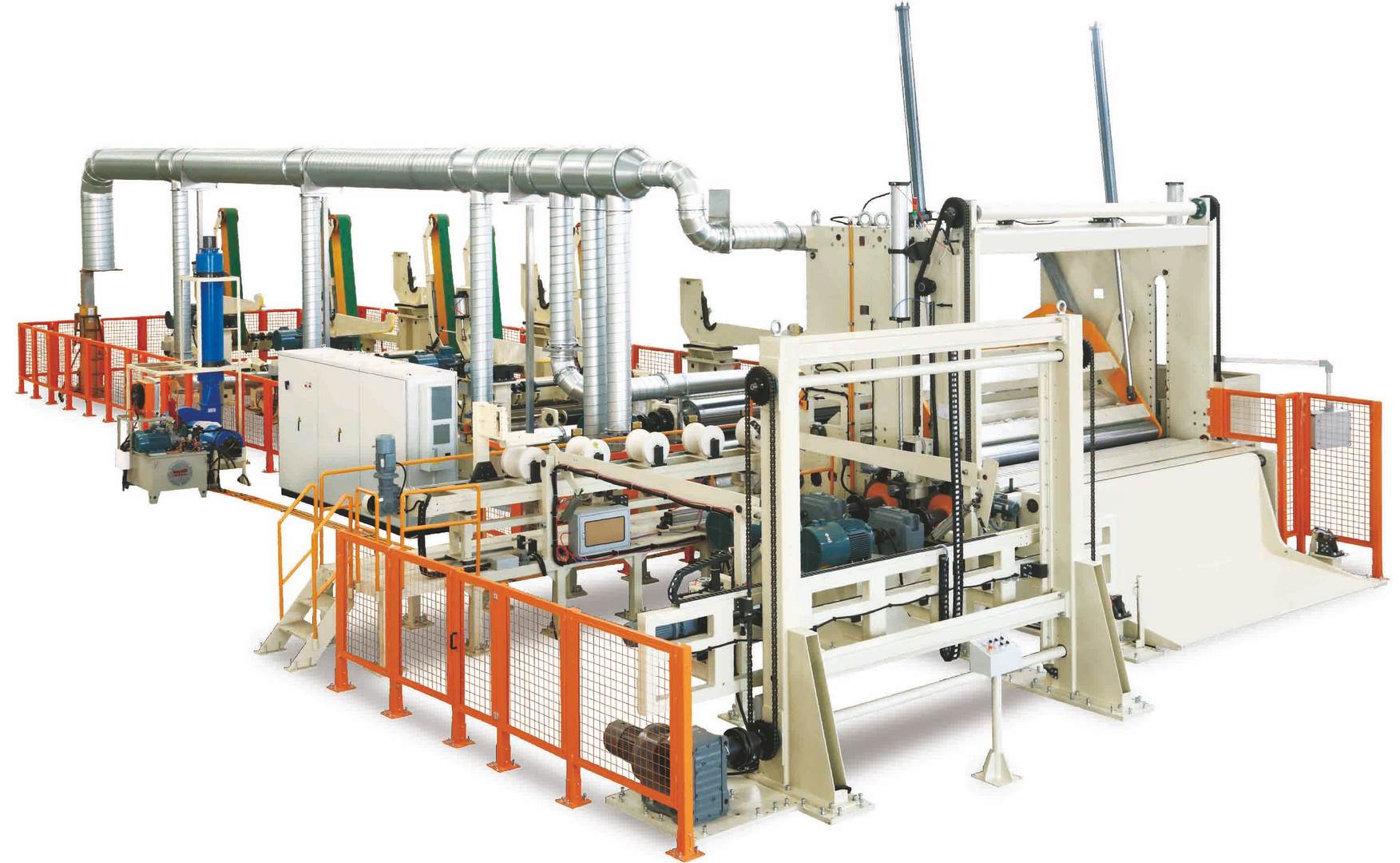

Superior Roll Consistency

Integrated automatic tension control and stable rewinding maintain sheet integrity and destination accuracy, ensuring consistent paper quality and dimensional conformity for downstream packaging.