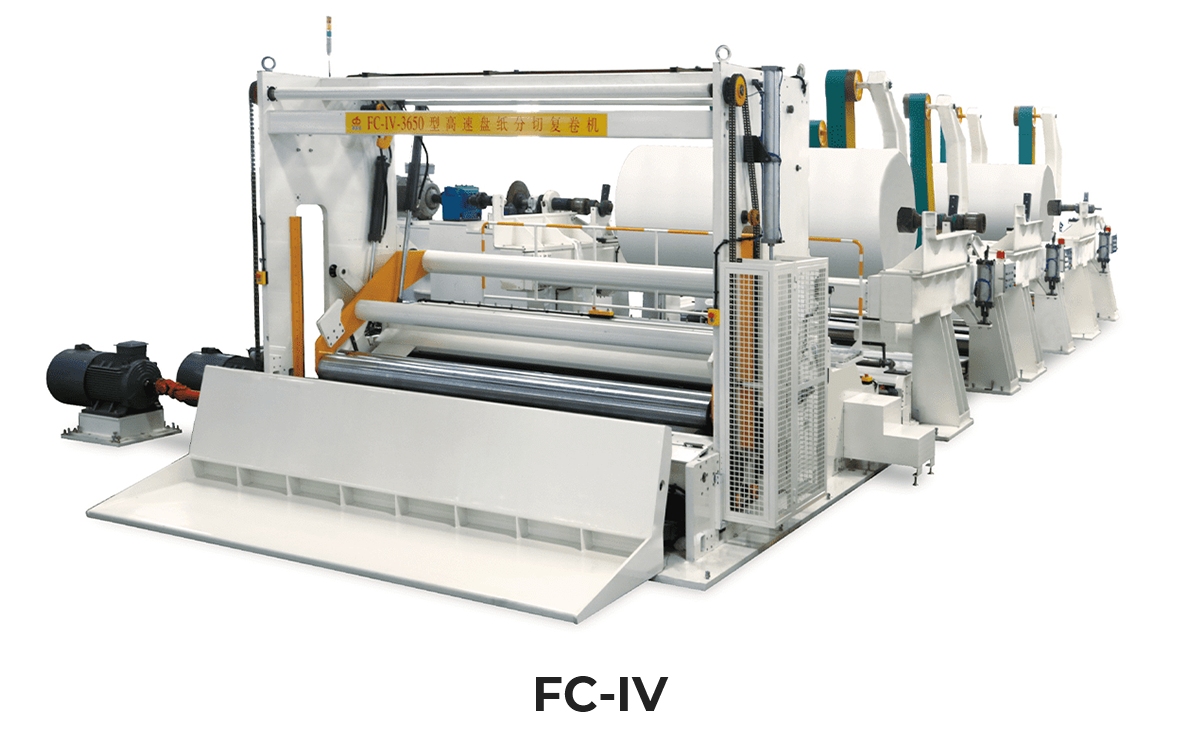

High Precision Cutting – The toilet paper cutting machine guarantees uniform roll sizes and smooth edges, improving overall product quality.

Versatile Applications – Functions as both a tissue cutting machine and a tissue paper cutting machine, suitable for various roll diameters and sheet counts.

Durable Construction – Engineered for long-term performance, reducing downtime and maintenance costs.

Easy Operation – User-friendly interface allows operators to adjust settings quickly, increasing efficiency in production runs.

Energy Efficiency – Designed to optimise power consumption, lowering operating costs while maintaining high output.

Global Standards – The toilet paper machine is manufactured to meet international safety and quality certifications, ensuring reliability across markets.

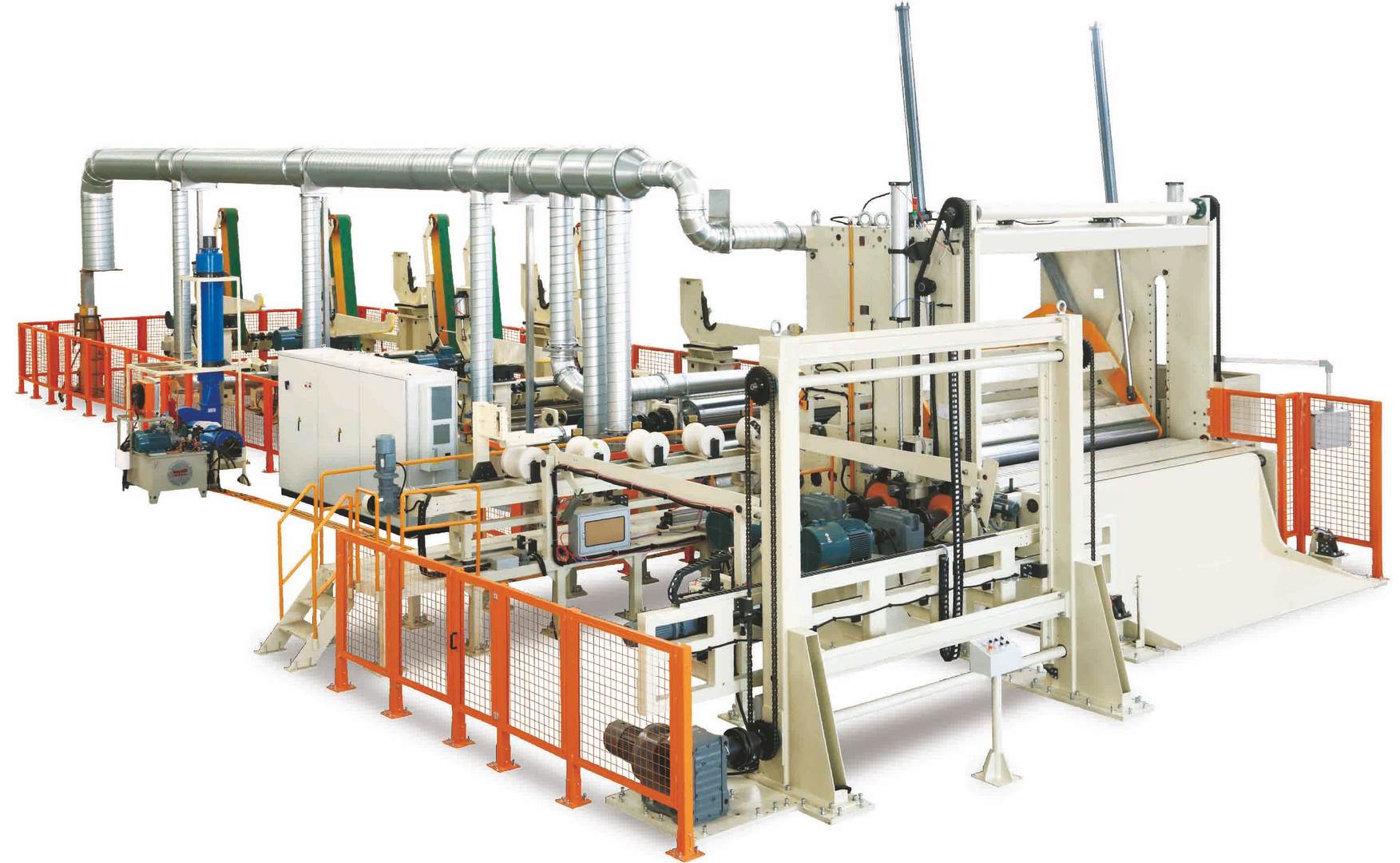

Choosing a machine from Foshan DeChangYu Paper Machinery Manufacture Co., Ltd. means partnering with a company that has been driving innovation in the paper converting industry since the 1980s. With over 60 national patents, ISO 9001:2015 and CE certifications, and recognition as a Guangdong High-tech Enterprise, DeChangYu is trusted by customers in 160+ countries and regions.

Proven Expertise – More than 30 years of experience in developing intelligent equipment for toilet paper, tissue, and kitchen towel production lines.

Strong R&D Capability – Industry-leading innovations, including the award-winning glue-free tail sealing machine, that improve efficiency and sustainability.

Quality & Precision – 100,000㎡+ factory area equipped with advanced machining and 6S lean production for superior product reliability.

Global Reach – Over 400 skilled employees and a service network that supports customers worldwide.

Customised Solutions – From toilet paper machines to tissue cutting machines, DeChangYu offers one-stop solutions tailored to diverse production needs.

Customer First – Guided by values of perfection, vitality, and innovation, every machine is designed with operator safety, efficiency, and long-term performance in mind.