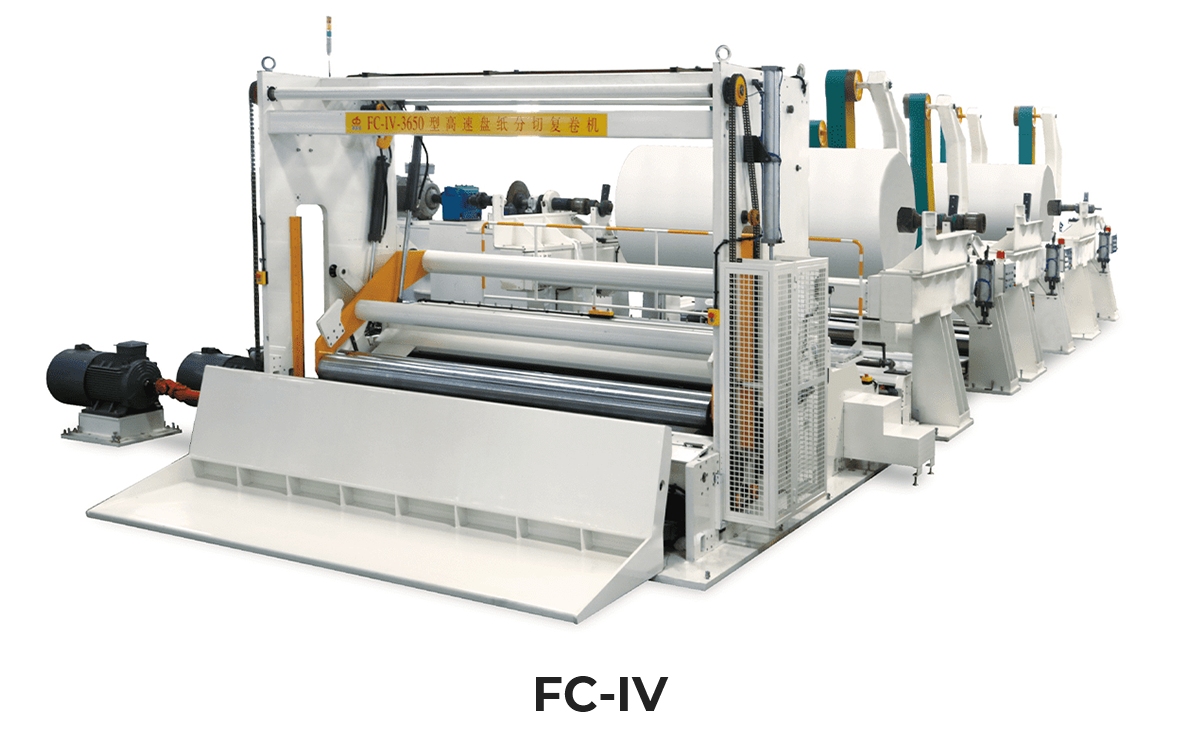

Advanced rewinding control system

The FC Series adopts an automatic pneumatic proportional valve to control linear slider rail lifting. A hydraumatic servo system precisely manages the riding roller, while pneumatic thimbles securely grip the core shaft, ensuring stable and accurate rewinding.

High-precision bottom slitting system

Equipped with a one-piece blade shaft and a full set of multi-blade knives, the slitting system delivers clean, accurate cuts and ensures consistent roll width throughout high-speed operation.

Optimised tension and roll edge control

Differential speed control between the front and rear rewinding rollers, combined with the riding roller, precisely regulates final roll tension and guarantees neat, well-aligned roll edges on both sides.

Flexible and efficient backstand design

The backstand supports both forward and reverse operation for easy machine handling. An independently driven guiding roller and a bottom-mounted web guiding platform help minimise paper elongation and reduce material loss.

Leading calender technology (optional)

Optional steel-to-steel calendering uses two chilled cast iron rollers, each driven by an independent motor. Pneumatic tyres apply adjustable pressure, while both the roller angle and gap size can be finely tuned for optimal surface quality.

Enhanced safety and tail trimming system

A tipper-hopper provides effective guarding during machine operation, while a water-based tail trimming system ensures clean and efficient tail finishing.

Automatic rewinding shaft feeding

The machine features an automatic rewinding shaft feeding function, improving operational efficiency and reducing manual handling.

Stable hydraulic and pneumatic lifting system

A hydraulic-controlled riding roller combined with pneumatic lifting of the reel core shaft ensures smooth operation and consistent pressure control.

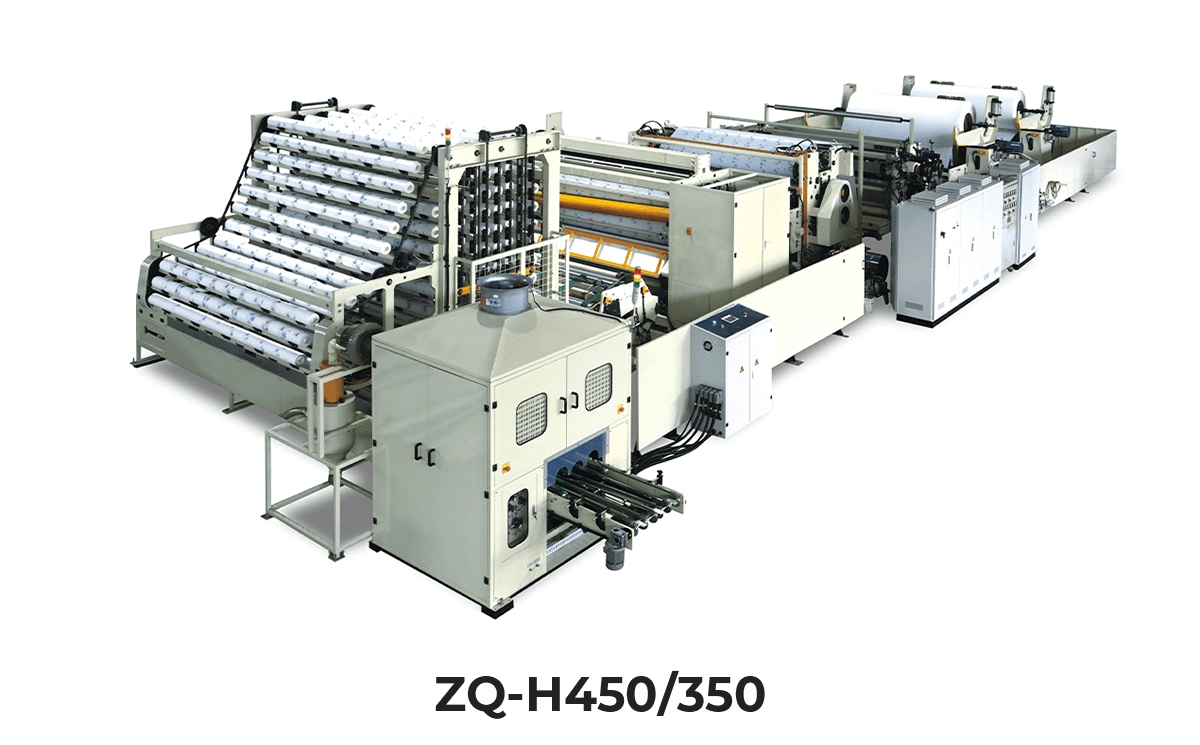

Centre-drive unwinder with tension sensing

The centre-drive unwinder is equipped with a web-tension sensor, allowing stable processing of tissue, packaging paper, and cultural paper with precise tension regulation.

Automatic pull-plug system (optional)

An optional automatic pull-plug system simplifies operation, reduces setup time, and further improves overall production efficiency.