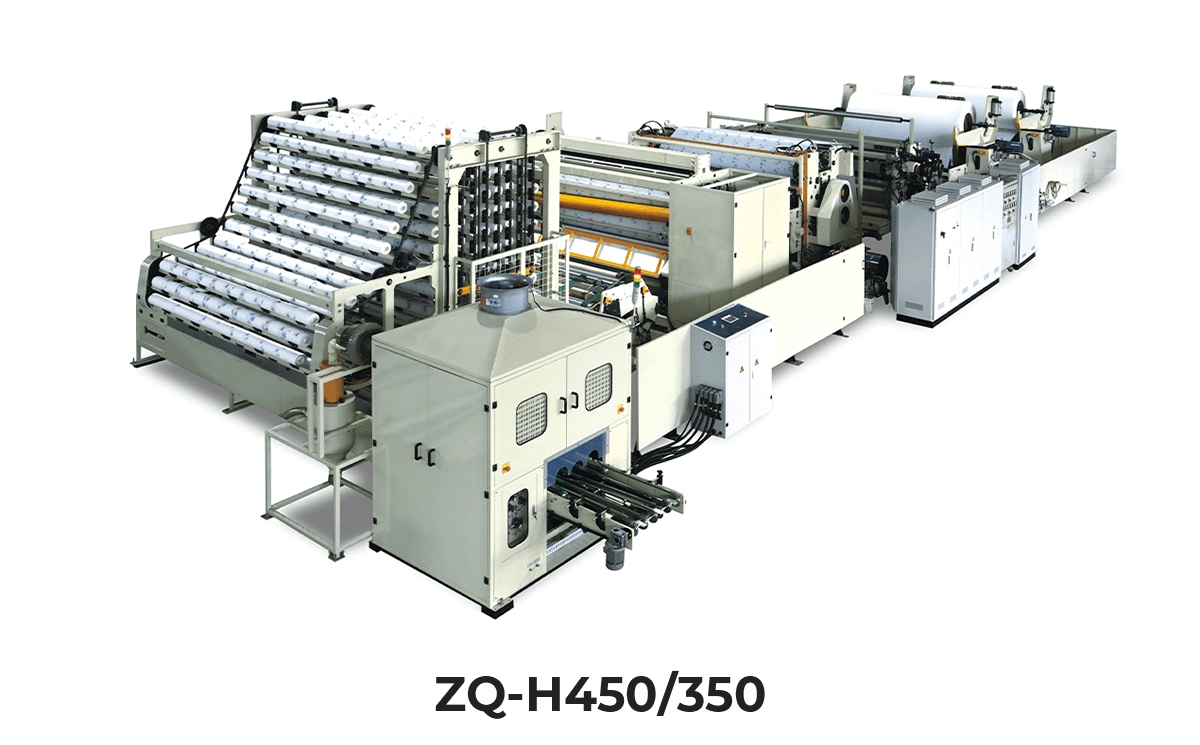

1. With professional net-pattern color printing ink roller on the color printing system, the patterns prined by this device will have better effect.

2. Raw paper will be sent to the polishing unit by synchronized belt, and sent to the embossing roller after polishing. Tension regulators are set between raw paper, polishing and embossing device.

3. Automatic stop protector for paper wind around the folding wheel.

4. Embossing with engraving mode can be equipped: Which can make engraving patterns be clearer, and the patterns will have stereo effect.

5. Steel to steel embossing device can be equipped, which can make the paper be more soft.

6. Automatic constant temperature heating device can be equipped on the embossing unit.