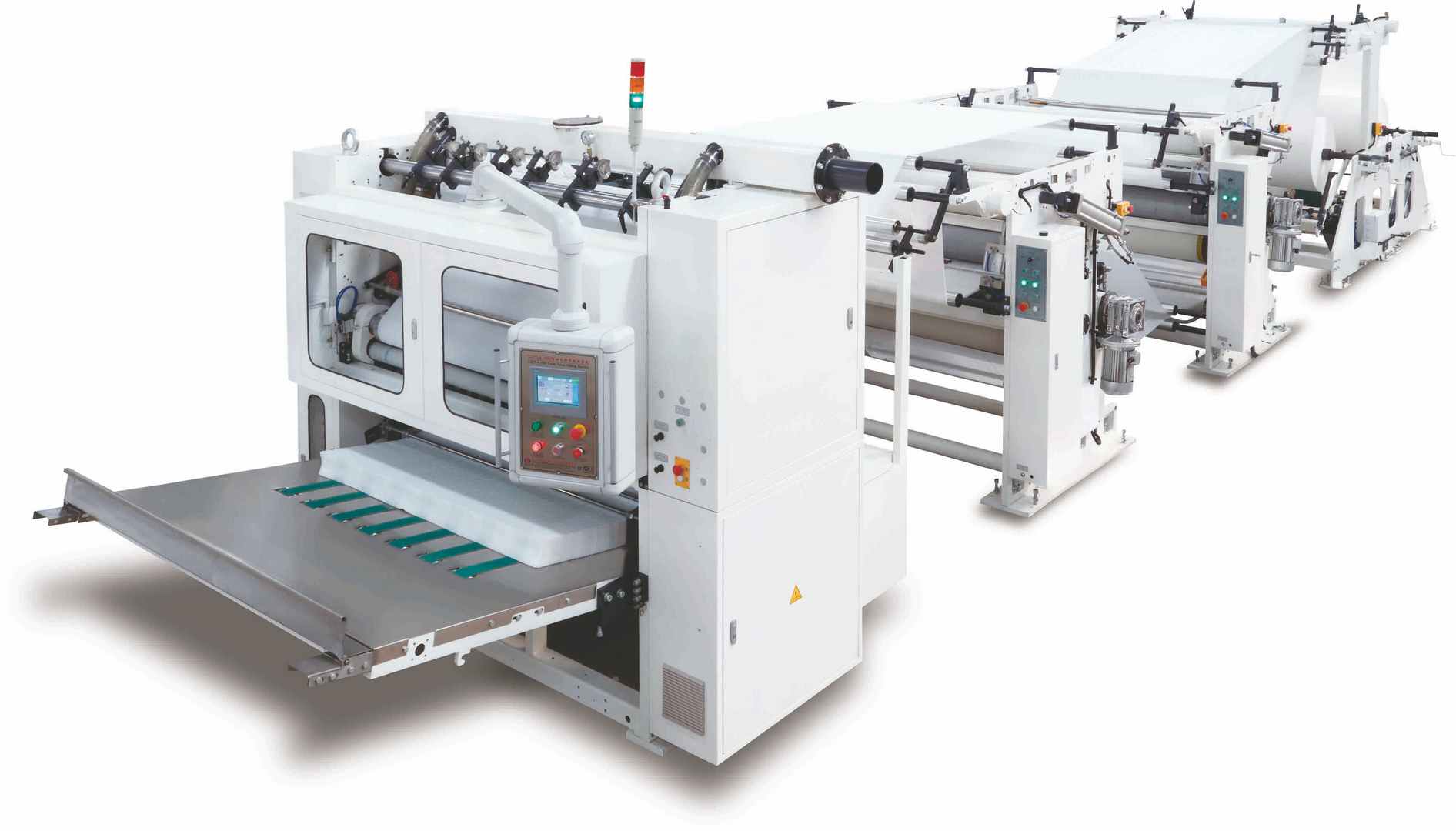

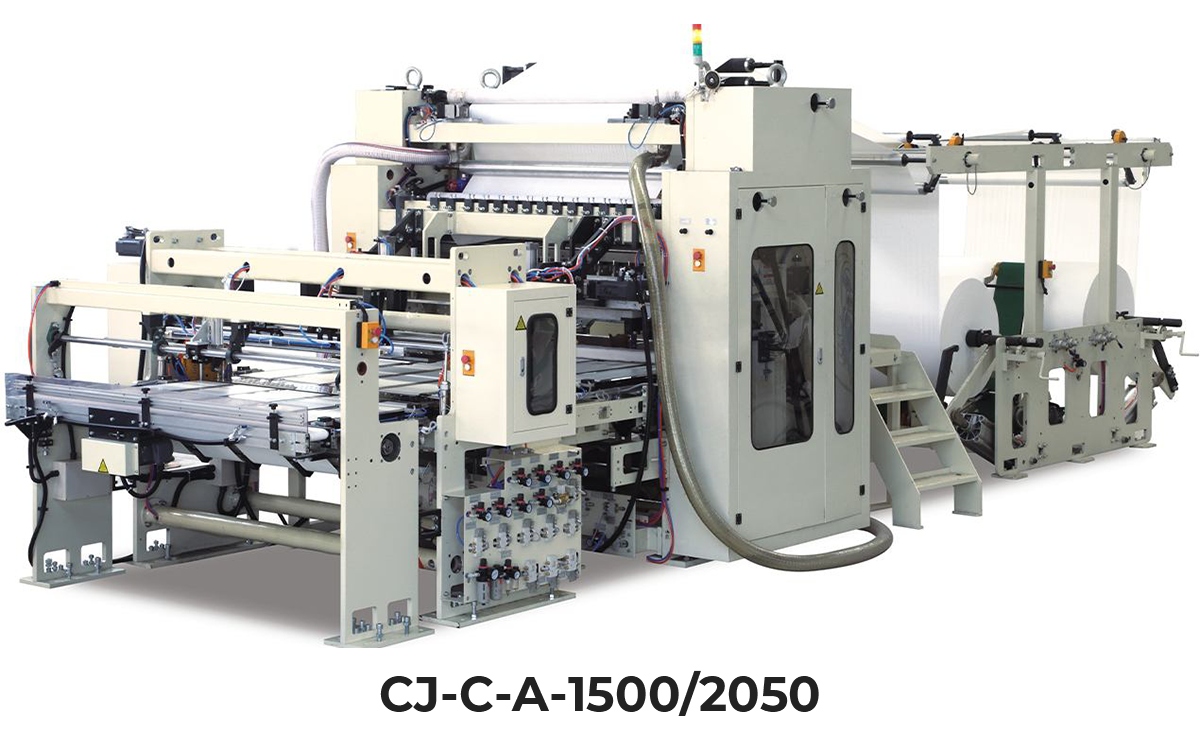

Ultra-High Folding Speed

Designed for high-output tissue lines, this interfolder machine facilitates rapid folding rates and supports multi-lane layouts—ensuring smooth flow from jumbo unwind to stacked product, as seen in professional interfolder systems.

Vacuum-Assisted Folding with Automatic Counting

Utilising a vacuum-suction folding mechanism combined with PLC control, the machine delivers reliable tissue handling, neat stacking, and automatic counting. This architecture ensures consistency and operator efficiency—a method also employed in advanced facial tissue converters.

Multi-Lane Configurability

Customized from 2 to 10 lanes per customer requirements, this tissue interfolder scales with your facility’s capacity demands—offering modular flexibility for phased expansion.

Integration-Ready Design

Built with automation in mind, the machine links effortlessly to upstream unwinding and downstream packaging systems. PLC/HMI interfaces and optional transfer units enable continuous tissue converting workflows.

This napkin folding machine shines in several production scenarios:

1. Facial Tissue Production Lines: Generating interfolded tissue stacks for soft‐pack or carton packaging.

2. Napkin Folding Operations: Ensuring high-precision folds—V-fold, Z-fold, interfold—for retail napkins or hospitality-grade dispensers.

3. Hygiene & Quick Dispensing Environments: Perfect for high-traffic areas such as hotels, healthcare, and public restrooms, where interfolded tissues minimize waste and maintain hygiene.