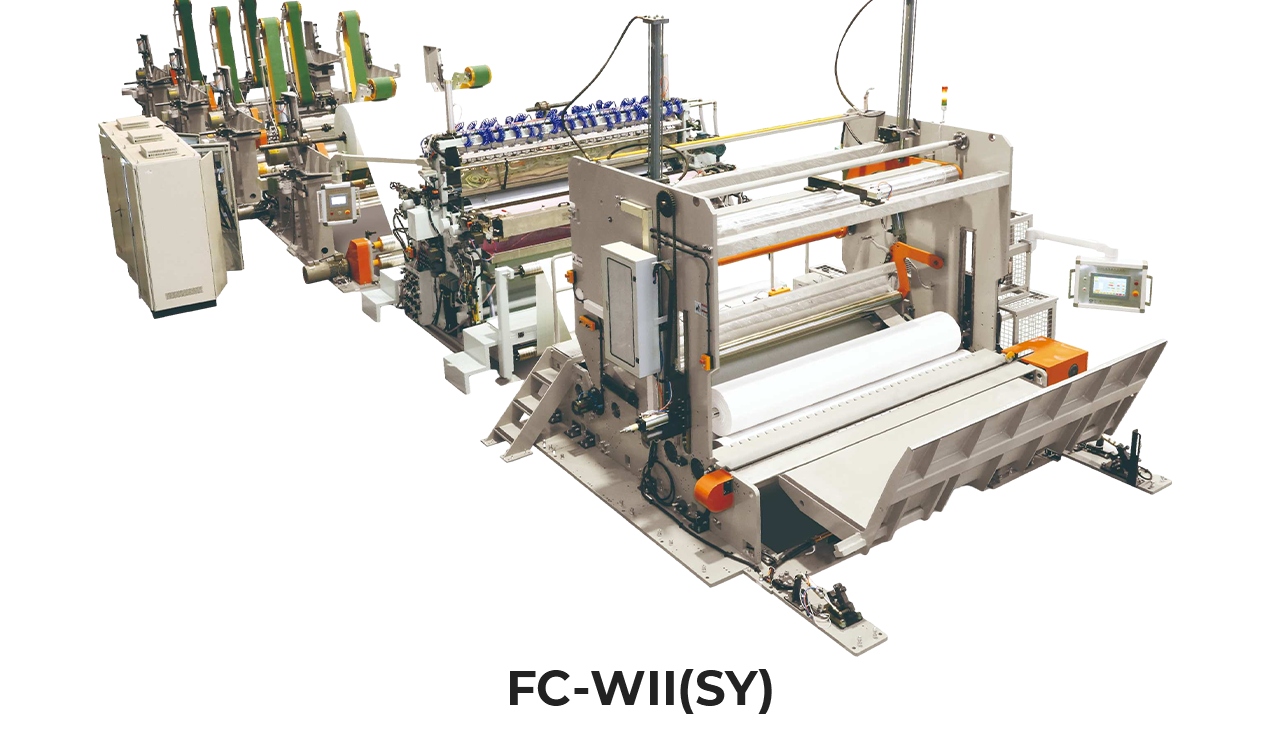

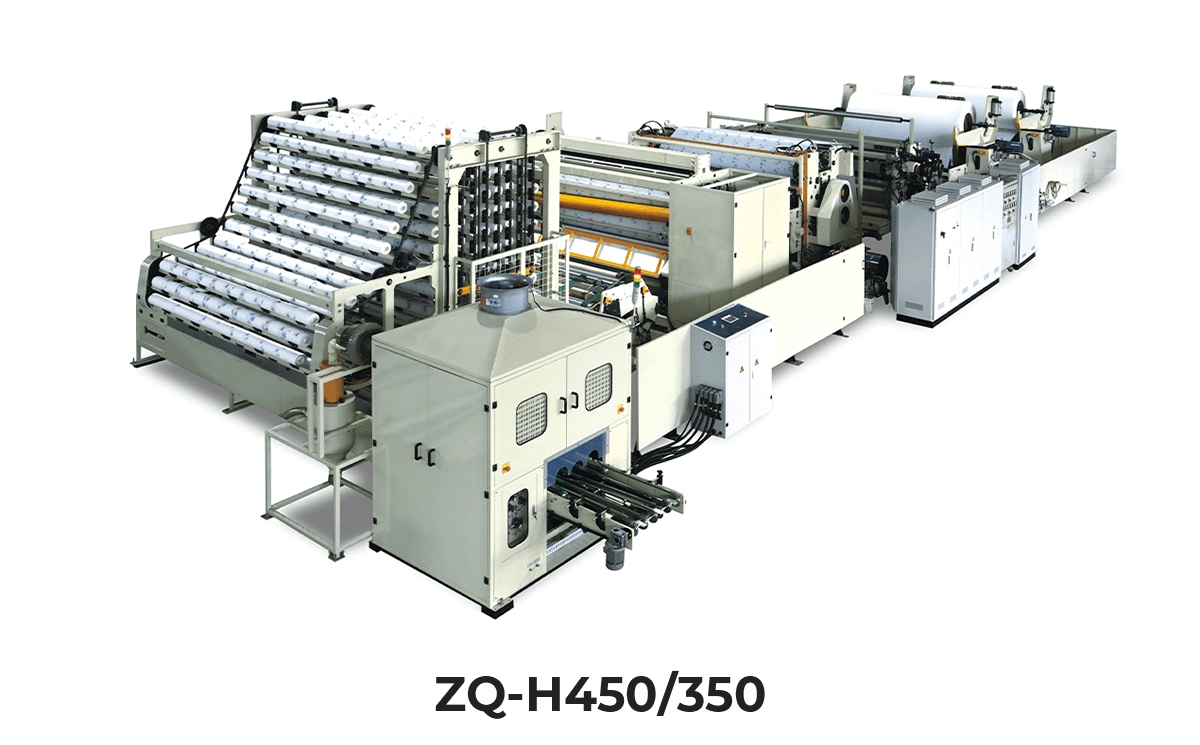

Our toilet paper printing machines are designed to bring your branding ideas to life, offering high-quality solutions for both commercial and custom applications. Whether you need to print toilet paper rolls for retail, promotions, or premium branding, our advanced machines provide exceptional performance and reliable results.

1. High-Speed Efficiency: Designed to handle large-scale production, ensuring seamless toilet tissue printing for high output demands.

2. Customisation Options: Perfect for creating toilet paper custom prints, adding logos, patterns, or promotional designs with vibrant precision.

3. Eco-Friendly Operation: Advanced technology ensures minimal waste and efficient use of resources during the printing of toilet paper.

4. User-Friendly Design: Easy-to-operate interface for quick setup and adjustments, catering to diverse toilet paper printing needs.