High-Precision Slitting & Cutting

Using a combination of rotary knives or band saw cutting technology, this toilet paper slitting machine ensures smooth, clean cuts across high-speed operations. The system supports both log slitting (whole roll cutting) and rewind slitting (web unwinding and rewinding), enabling versatile handling of jumbo rolls depending on line configuration.

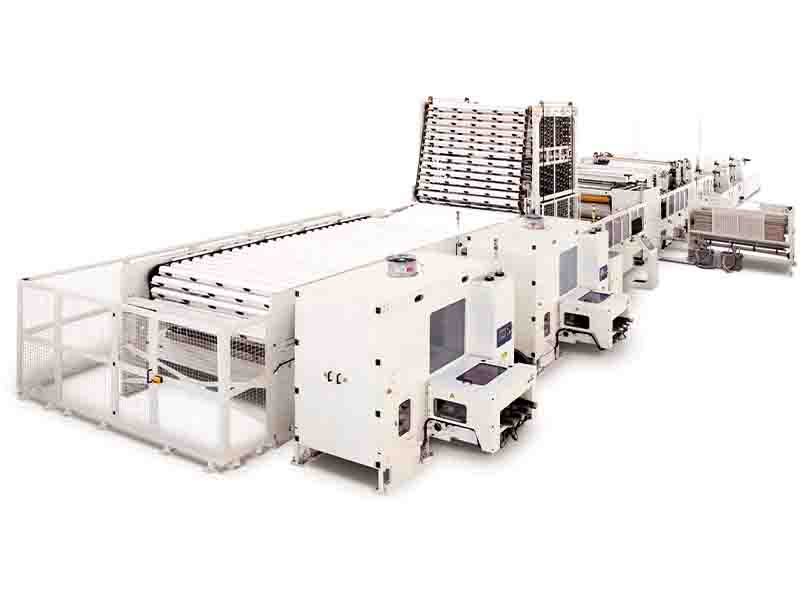

Continuous Automatic Operation

Built for industrial-grade production, the machine automates core slitting, roll length cutting, and rewinding. Integrated PLC and servo controls maintain tension, automatically align knives, and reduce manual interventions—boosting efficiency and reducing operator fatigue.

Wide Range of Compatibility

Designed to process jumbo rolls with diameters and widths as needed, this system accommodates different core sizes and variable perforation pitches. Post-slitting, the resulting toilet rolls are ready for folding or packaging, aligning with both soft-pack and rigid-pack formats.

Versatile & Modular

Can be deployed as a standalone tissue paper cutting machine or seamlessly integrated into a broader converting system—including embossing, folding, and packaging.

Superior Component Control

Features tension-optimized unwind systems, automatic knife positioning, and real-time PLC management for consistent toilet roll cutting machine performance.

Built for Productivity

Suitable for industrial-scale operations targeting high output with superior cut quality and system reliability.

Lean Maintenance Design: Designed for easy blade changes and minimal downtime, keeping production continuous and efficient.

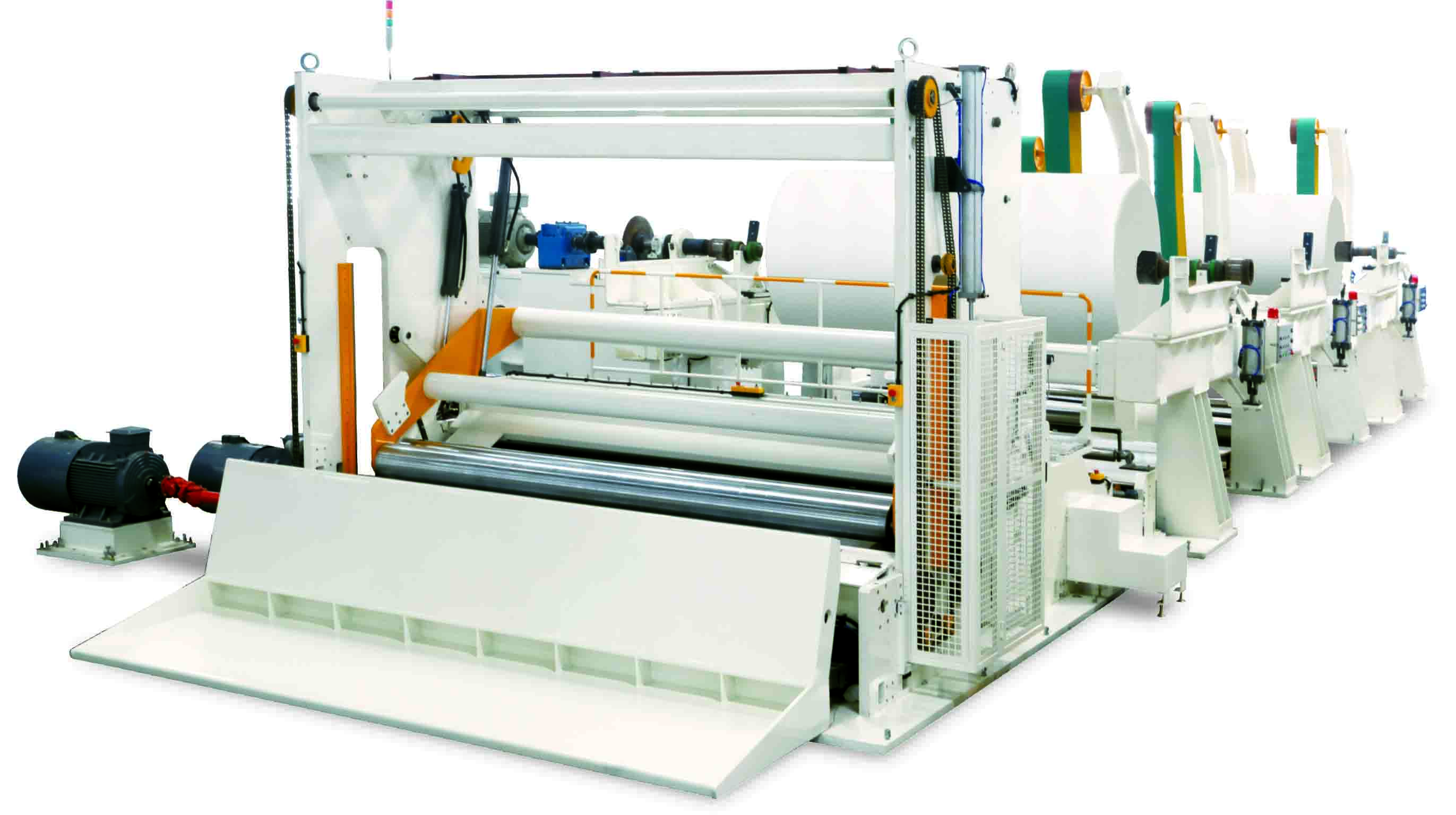

| FC-II Slitting rewinder |

|---|

| Max width of jumbo roll 2200/2900mm |

| Production speed 250-300m/min |

| Max diameter of finished product 1200mm |

| Min slitting width 150mm |

| Side-trimming width 25-50mm |

| Side-trimming system (From rewinder to collecting box) |

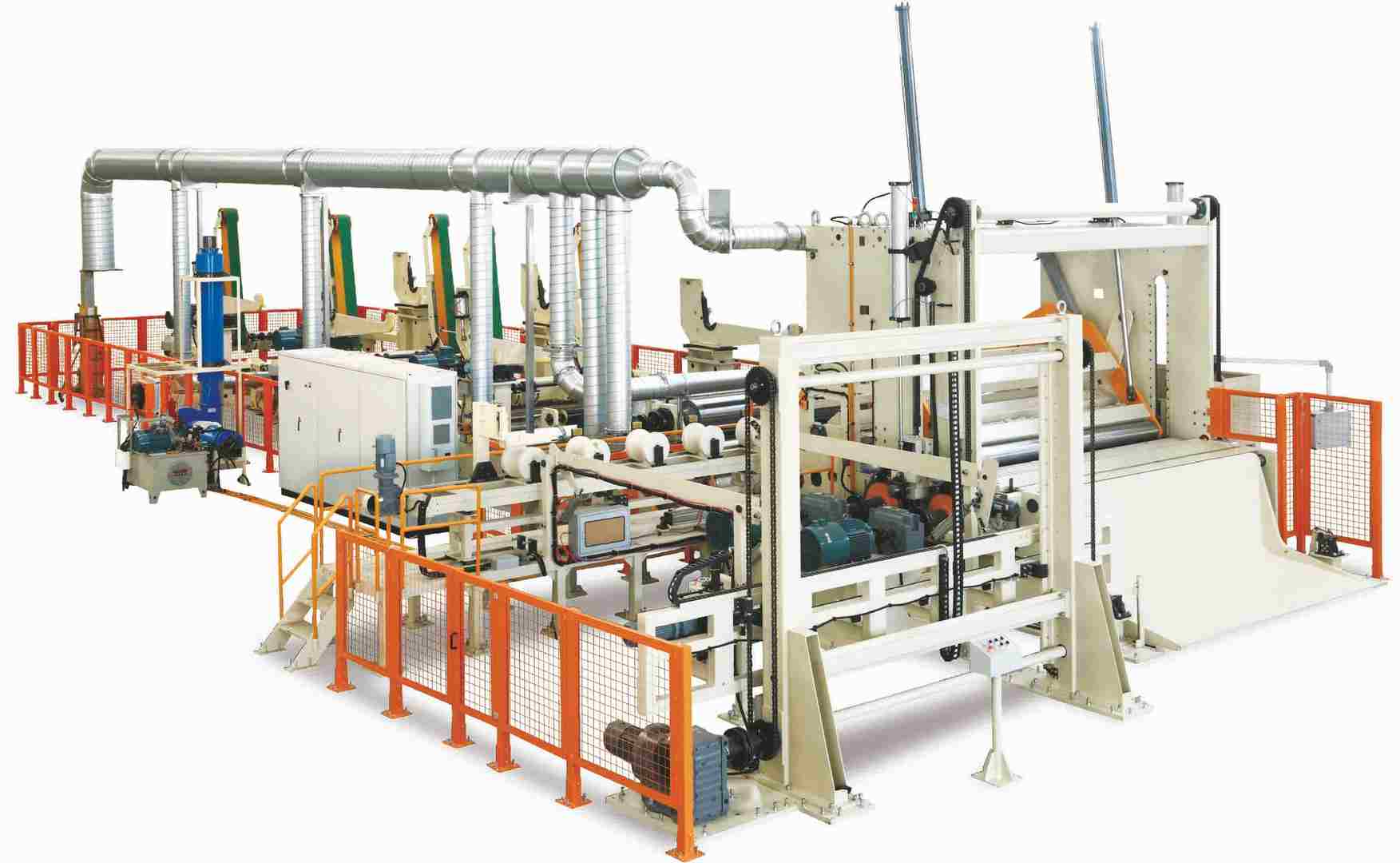

| FC-WX Slitting rewinder |

|---|

| Max width of raw paper 2850/3700mm |

| Production speed 1000~1200m/min |

| Max diameter of finished product φ1800mm, (φ2300, Others please specify) |

| Min slitting width 90mm |

| Side-trimming width 25-50mm |

| Pneumatic upper blade, multi-edged bottom blade |

| Optional |

|---|

| Backstand | 1-5 Layers, shaft type/shaftless type |

| Calemder | |

| Automatic pull/plug shaft system | |

| Side-trimming system | From rewinder to collecting box/to pulper |

| Hydraulic-adjust spreading roller | |

| Expending bottom blade shaft+multi blade slitting ring | |

| Tail cutting | Water blade/cross cutting blade |

| Fast-change unwinder |

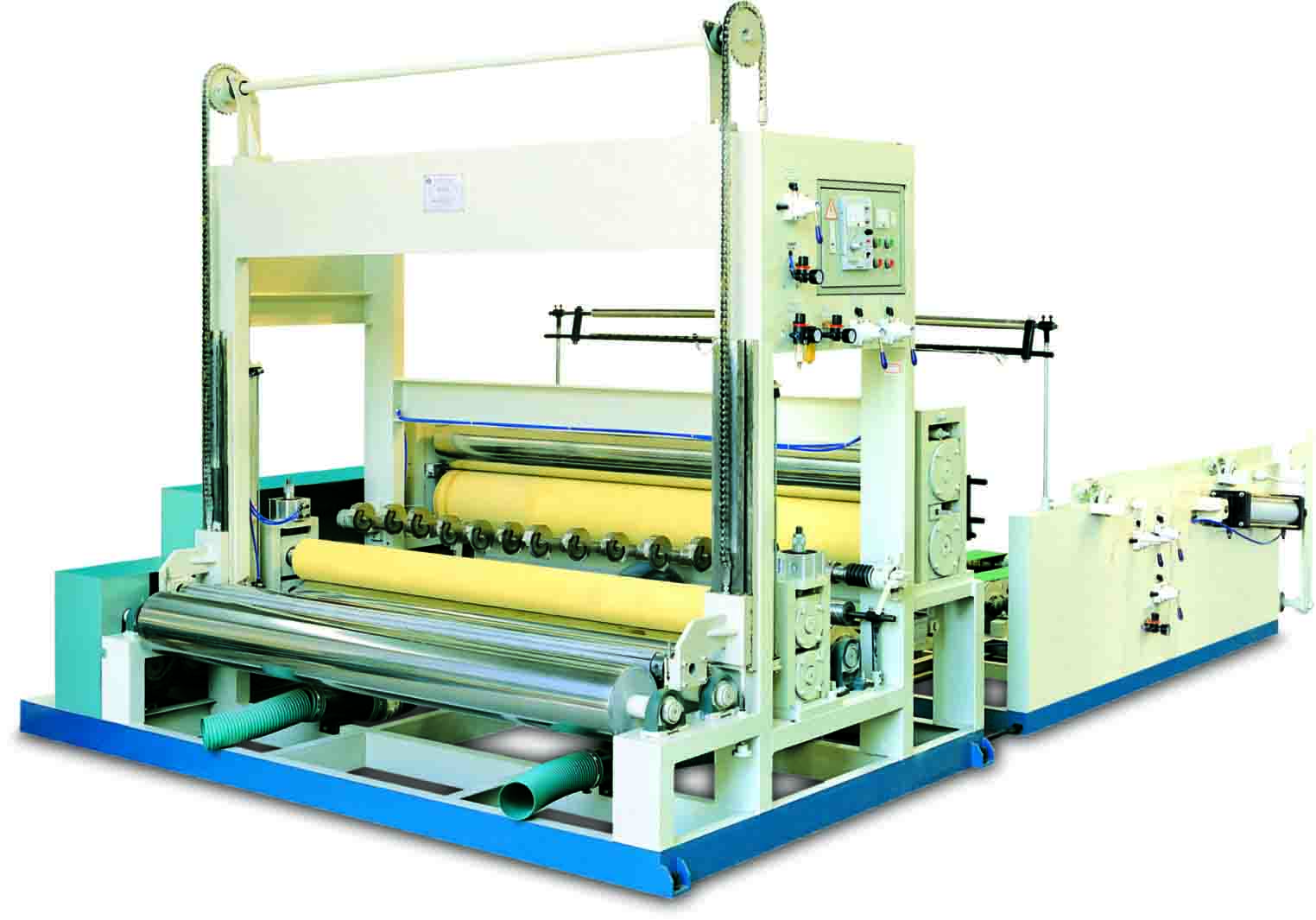

| FC-WIX Slitting rewinder | |

|---|

| Max width of raw paper | 2850/3700mm |

| Production speed | 1000m/min |

| Max diameter of finished product | φ1600mm |

| Min slitting width | 90mm |

| Side-trimming width | 25-50mm |

Pneumatic upper blade multi-edged bottom blade

| Optional | |

|---|

| Backstand | 1-5 Layers, shaft type/shaftless type |

| Calendar | |

| Automatic pull/plug shaft system | |

| Side-trimming system | From rewinder to collecting box/to pulper |

| Hydraulic-adjust spreading roller | |

| Expending bottom blade shaft+multi blade slitting ring | |

| Tail cutting | Water blade/cross cutting blade |

| Fast-change unwinder |

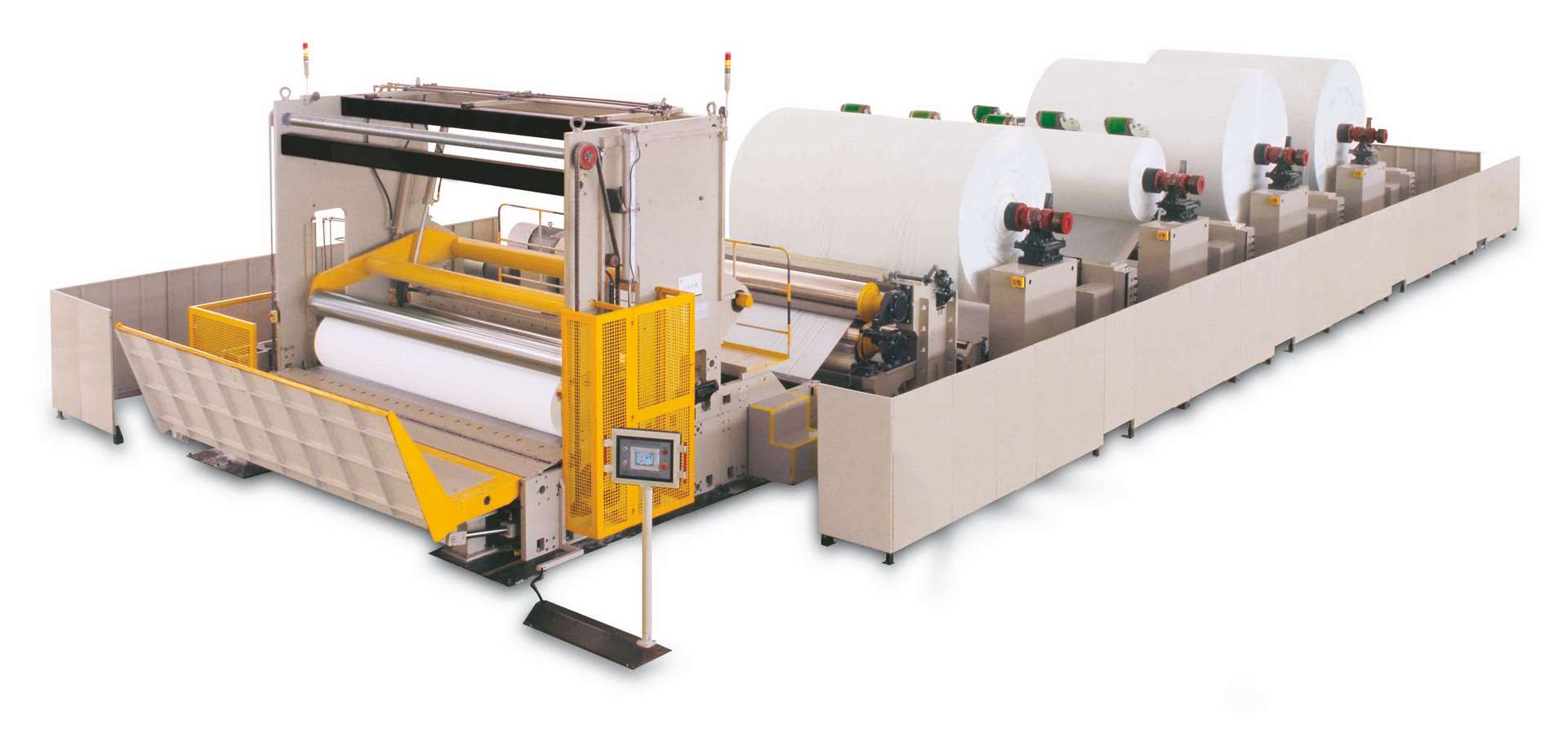

| FC-IV Slitting rewinder | |

|---|

| Max width of raw paper | 2850/3700mm |

| Production speed | 1000~1200m/min |

| Max diameter of finished product | ø1800mm, (ø2300, Others please specify) |

| Min slitting width | 90mm |

| Side-trimming width | 25~50mm |

| Pneumatic upper blade, multi-edged bottom blade |

| Optional | |

|---|

| Backstand | 1–5 Layers, shaft type/shaftless type |

| Calendar | Automatic pull/plug shaft system |

| Side-trimming system | From rewinder to collecting box/to pulper |

| Hydraulic-adjust spreading roller | |

| Expending bottom blade shaft+multi blade slitting ring | |

| Tail cutting | Water blade/cross cutting blade |

| Fast-change unwinder | |

| Unwinding frame tension roller system constant unwinding web tension | |

| Dust removal system |