Boost your converting efficiency with our Automatic Tissue Roll Production Line for Kitchen and Toilet Rolls—a fully integrated, high-speed solution designed for manufacturers seeking excellence in tissue production line automation.

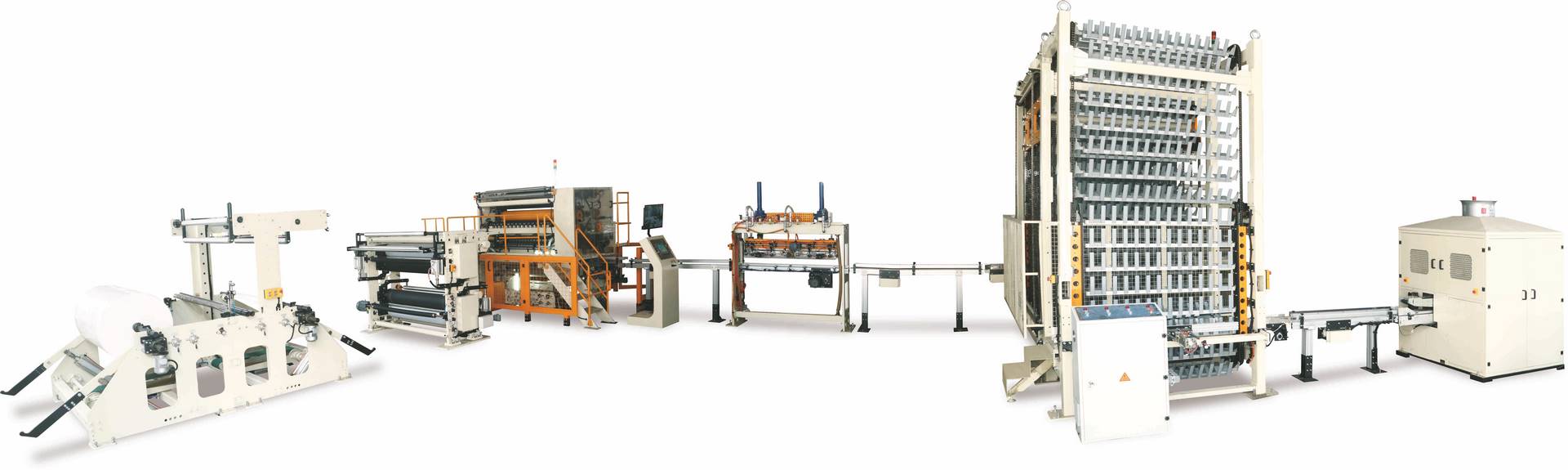

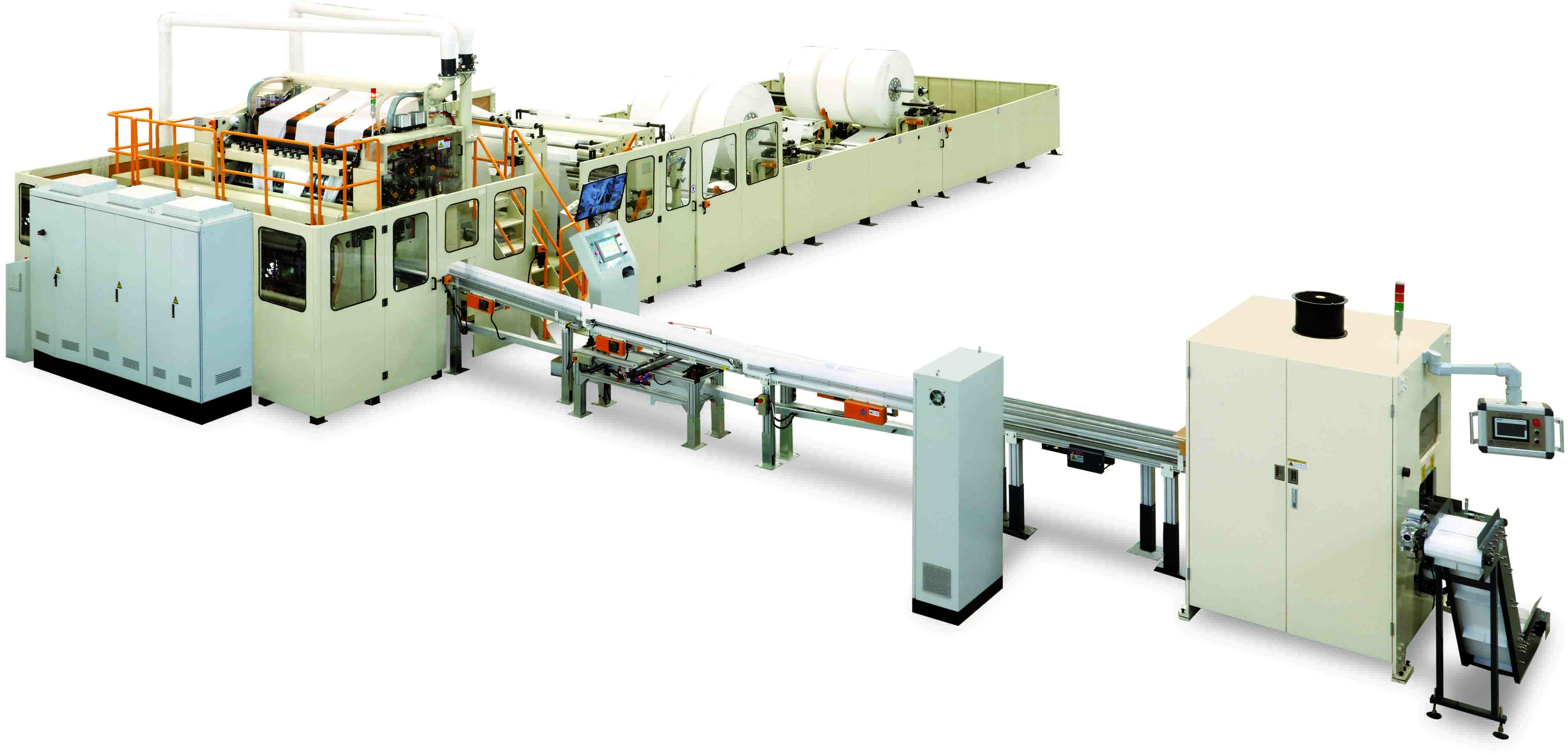

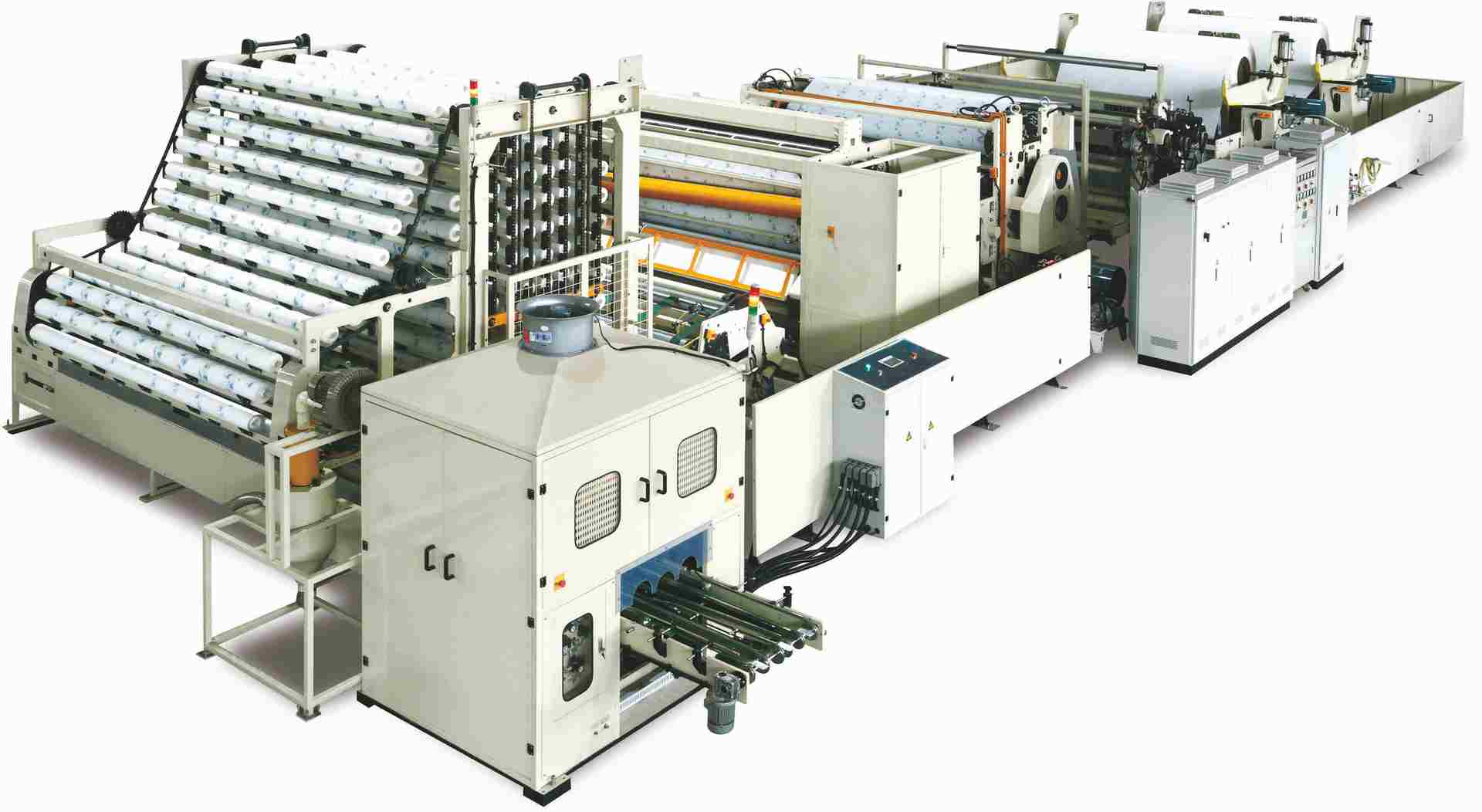

Whether you're producing toilet rolls for the retail market or kitchen paper towels for household or commercial use, this advanced line combines unwinding, embossing, perforating, rewinding, and cutting into a seamless, operator-friendly system. Optimised for both toilet roll production lines and kitchen roll production lines, it supports multiple core sizes, roll lengths, and embossing patterns to suit varied market demands.

Key Features:

High-speed operation with stable web control and low downtime

Servo-driven systems for accurate perforation and rewinding

Dual embossing options for improved texture

Compatible with laminated or single-ply tissue paper

Integrated log saw and packaging system available on request

Why Choose This Tissue Production Line?

Suitable for large-scale converters and OEM suppliers

Customisable for branded or private label manufacturing

Supports both standard and jumbo roll formats

As a trusted supplier of toilet roll production lines and kitchen roll production lines to over 160 countries, DeChangYu delivers proven technology, CE/ISO certifications, and comprehensive after-sales support.

Contact us for technical specifications, layout planning, or a customised quotation.