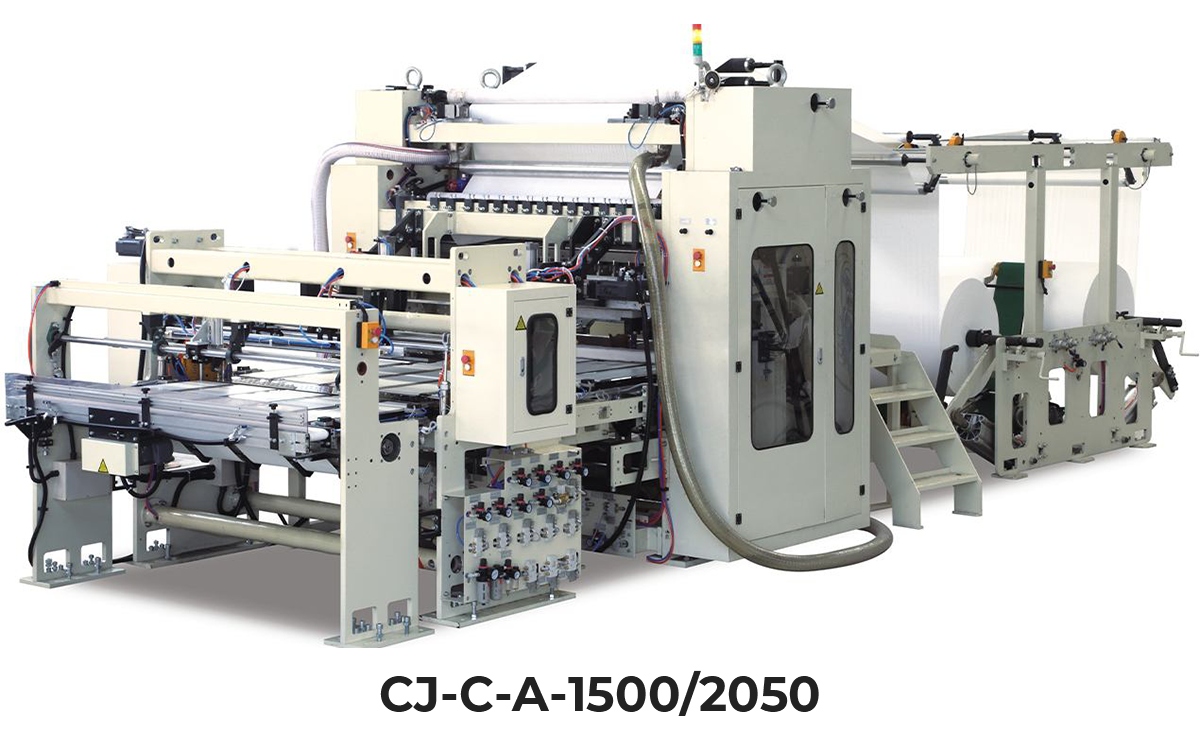

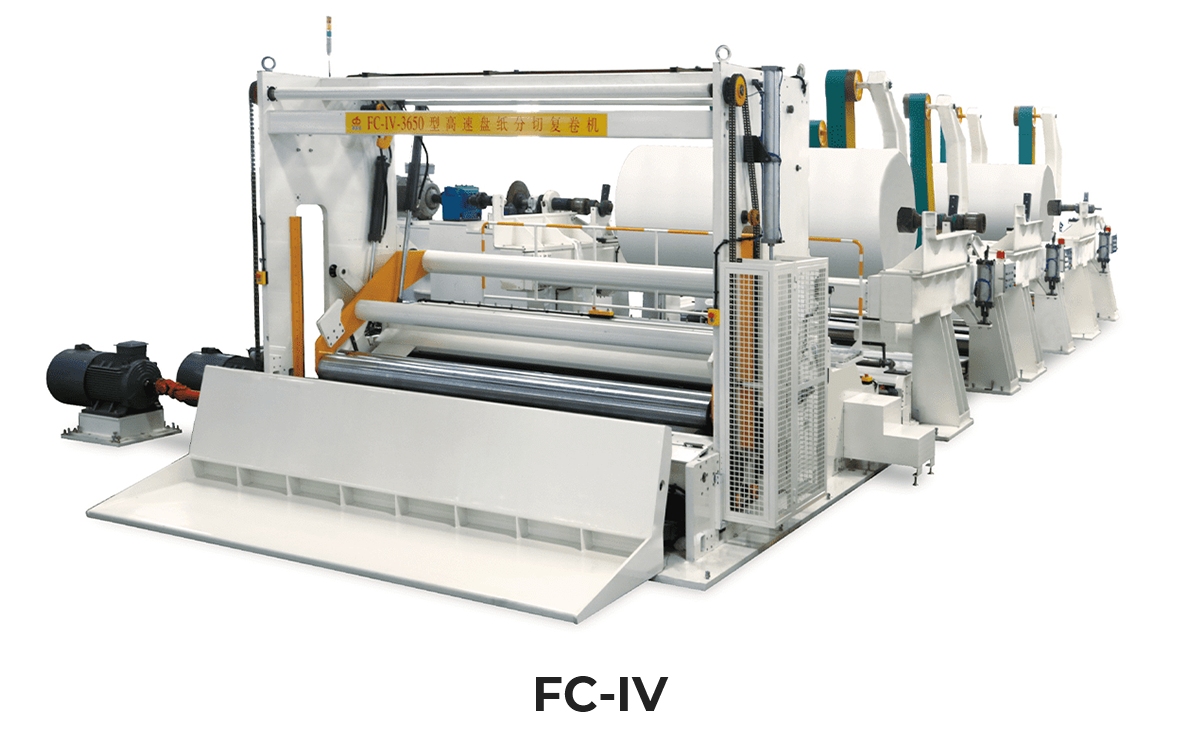

This v-fold facial tissue production line is composed of following machines:

- Unwinder-2 sets

- Glue-free laminating (2 Units)-1 set

- CJ-C-A series folding main machine -1 set(1200 Sheet\s/min)

- 90-Degree half folding and overturning unit-1 set

- DH-lll single channel horizontal log saw cuter-1 set (0-100 Cuts/min)

- Bottom pull single packing machine -1 set(30-50 Packs/min)

- 180-Degree half folding and overturning unit-1 set

- Log accumulator

- DH-ll single channel log saw cutter -1 set(0-300 Cuts/min)

- Single packaging machine--1 unit (150-180 Packs/min)

- Bundle packing machine- 1 set (18-30 Packs/min)

- Cartoning machine -1 set (10-20 Boxes/min)