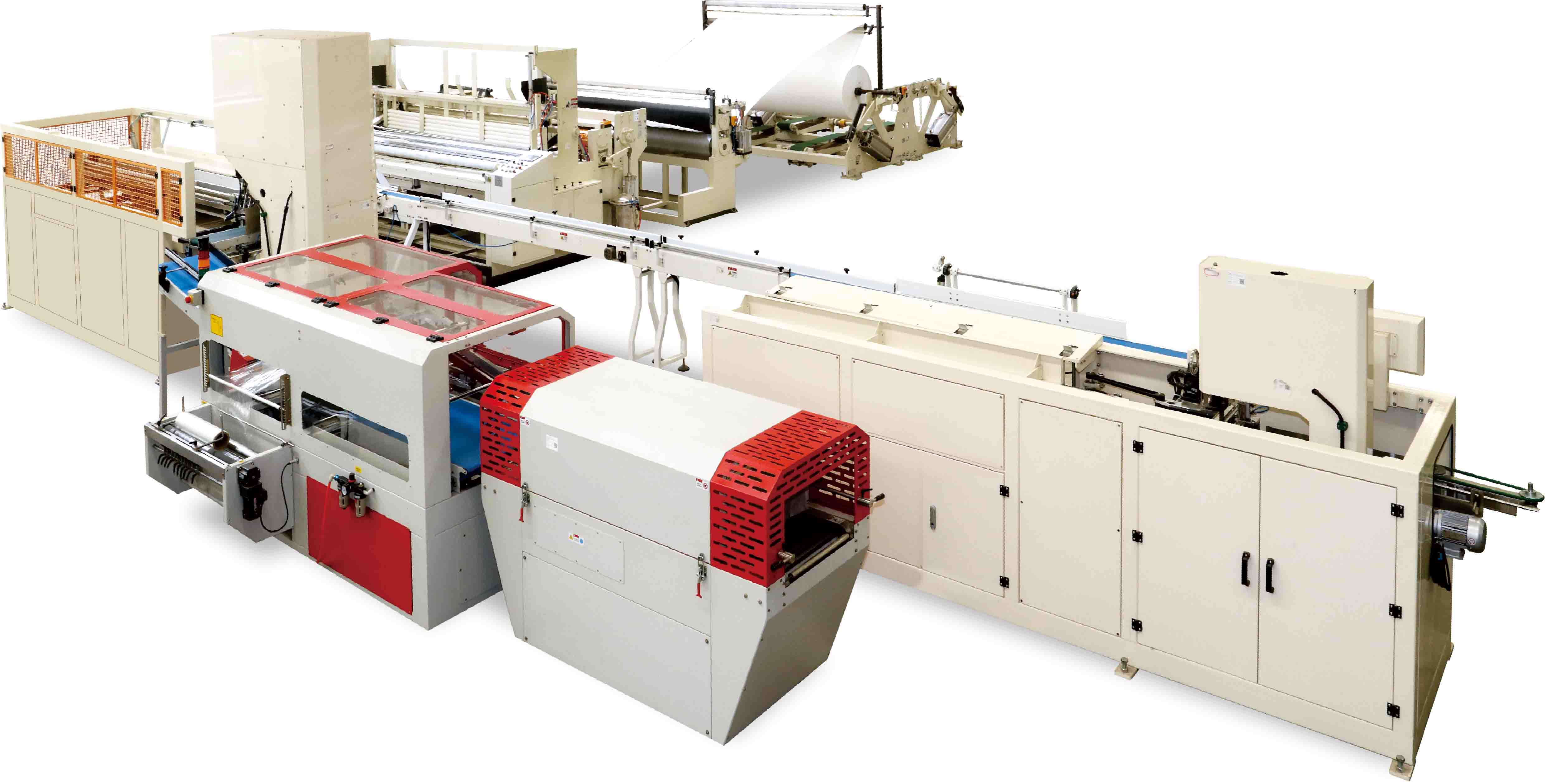

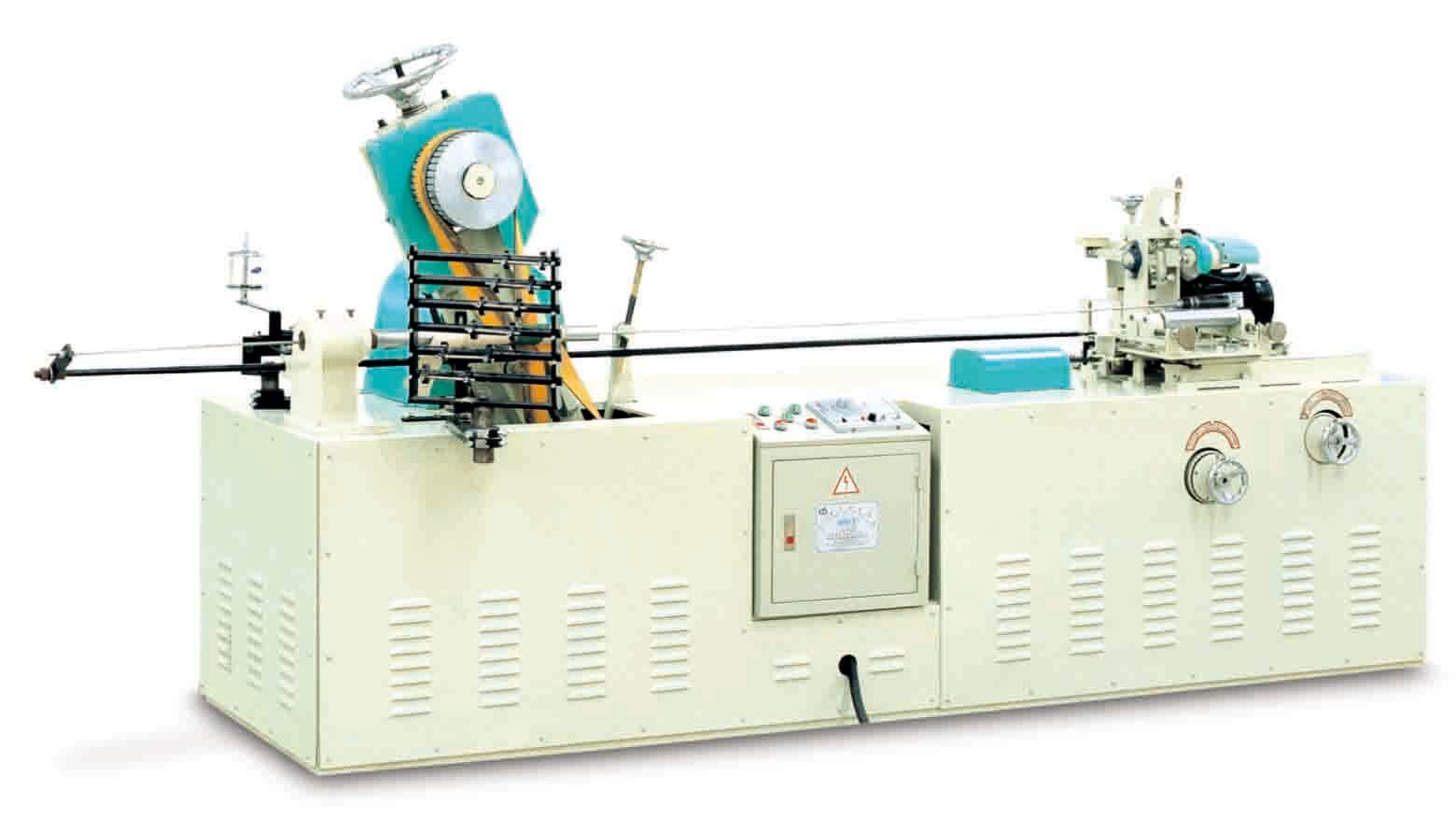

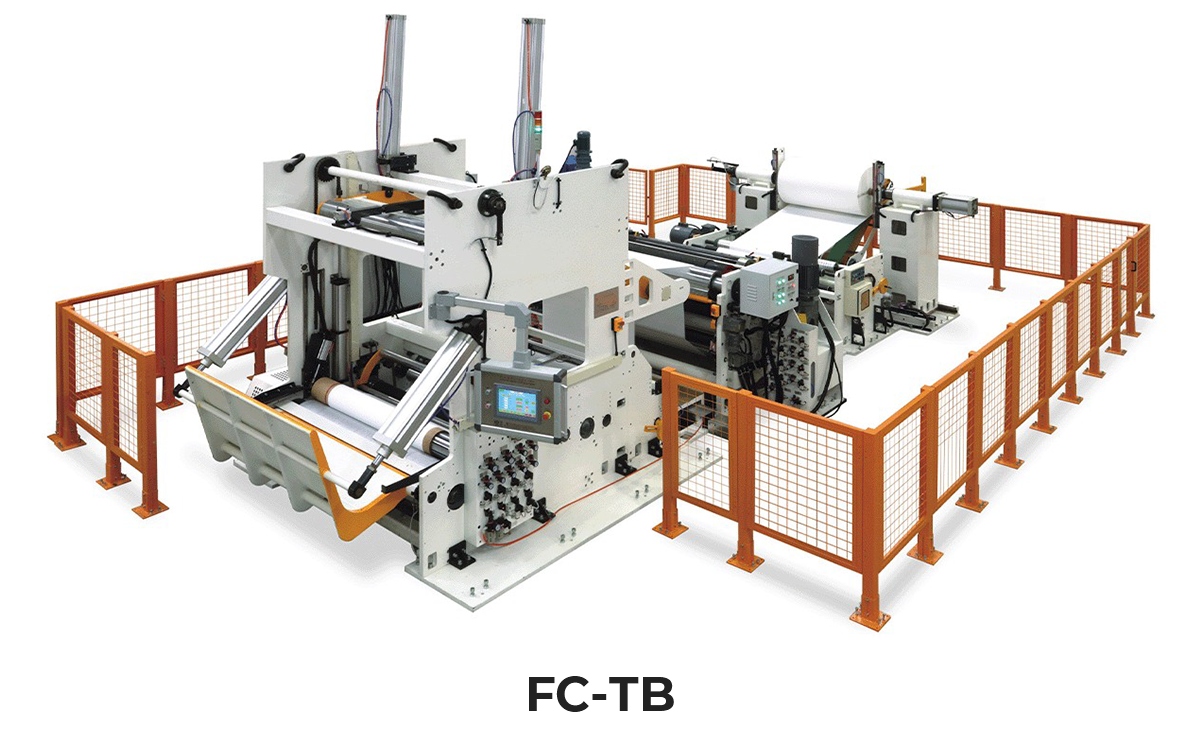

The Automatic Tissue Rewinder Machine from DeChangYu delivers high-speed and stable rewinding performance for JRT rolls, toilet paper, and kitchen towel production. Built on over 30 years of expertise, it combines precise tension control, accurate perforation, and smooth rewinding to ensure consistent, high-quality finished logs.

Backed by 60+ patents and certified to ISO 9001:2015 and CE standards, the machine offers advanced automation, low waste, and reliable hygiene benefits. Trusted in 160+ countries, DeChangYu’s tissue rewinder machine is ideal for manufacturers seeking efficiency, durability, and modern production capability.