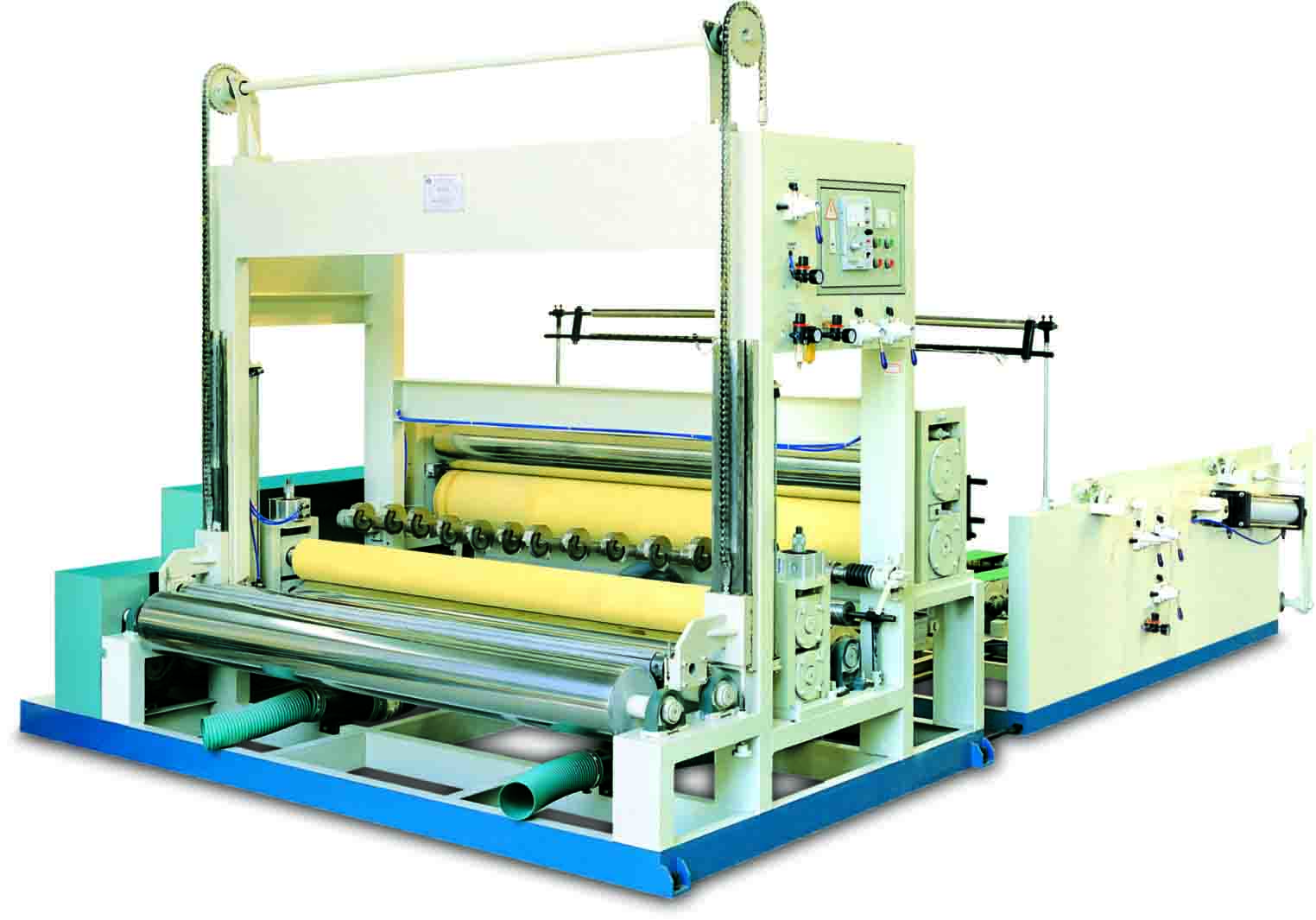

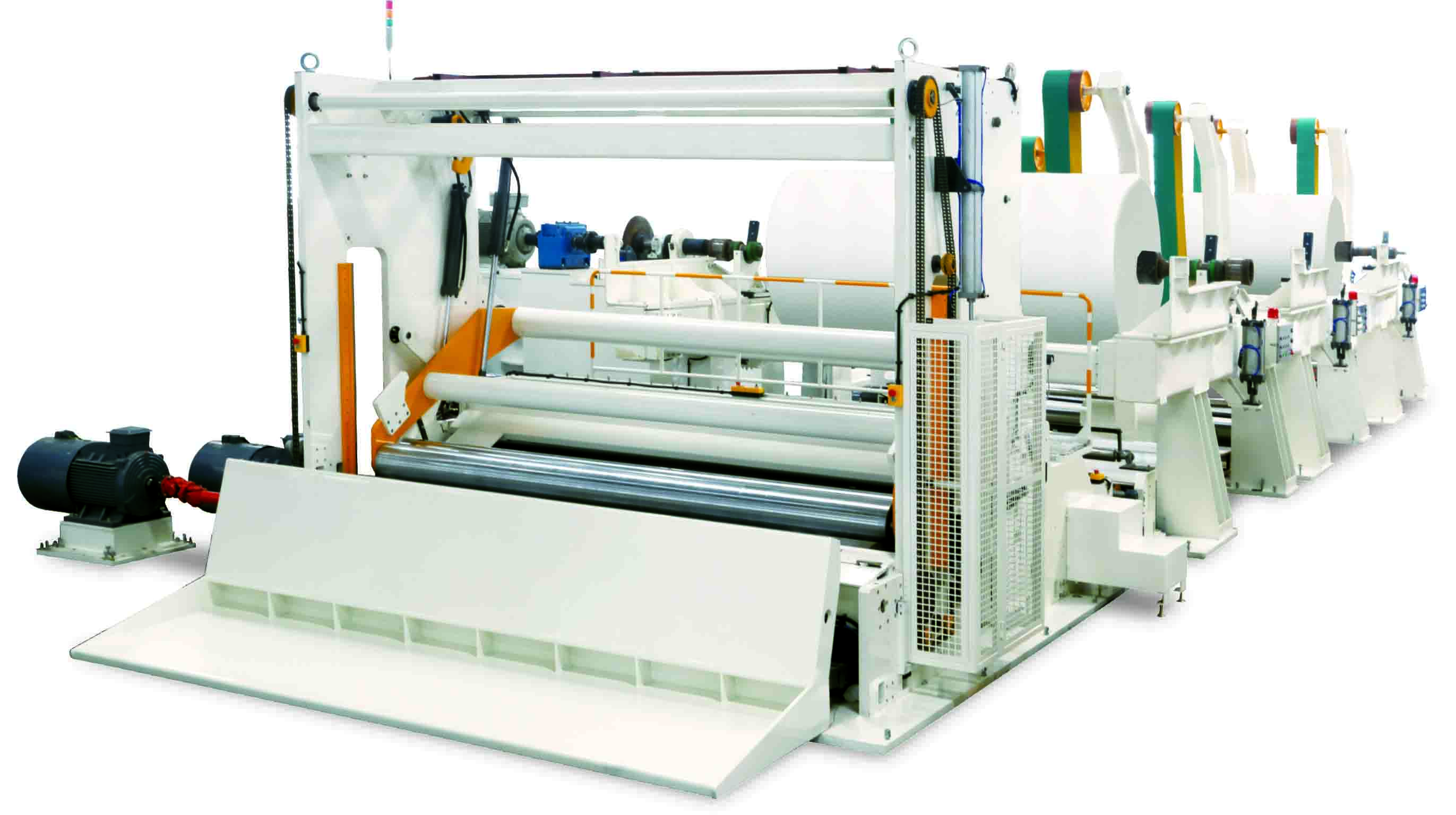

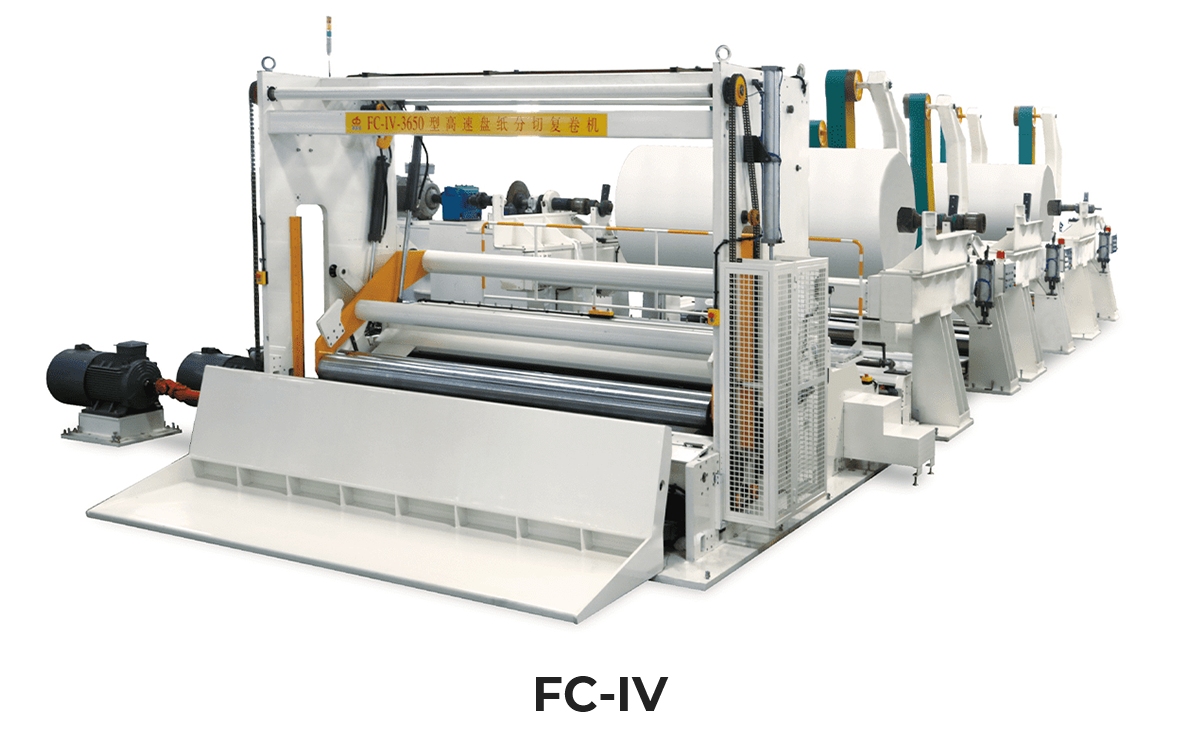

Fully Automatic Operation

The tissue paper cutting machine operates with advanced automation, reducing manual handling and ensuring stable, continuous production within high-speed tissue converting lines.

High Cutting Precision

Equipped with accurate length control and sharp cutting systems, the machine delivers clean, uniform cuts that improve finished roll appearance and consistency.

Stable High-Speed Performance

Designed for continuous operation, this tissue paper cutting machine maintains reliable performance even at high speeds, increasing overall production efficiency.

Low Waste, High Yield

Precise cutting and intelligent control systems minimize material loss, helping manufacturers reduce waste and improve cost efficiency.

Easy Integration into Converting Lines

The machine is engineered to integrate seamlessly with rewinders, embossing units, and packaging systems, supporting fully automated tissue converting lines.

User-Friendly Control System

An intuitive interface allows operators to adjust cutting parameters quickly, reducing setup time and simplifying daily operation.

Durable Industrial Design

Built with robust components for long-term reliability, the tissue paper cutting machine ensures low maintenance requirements and extended service life.